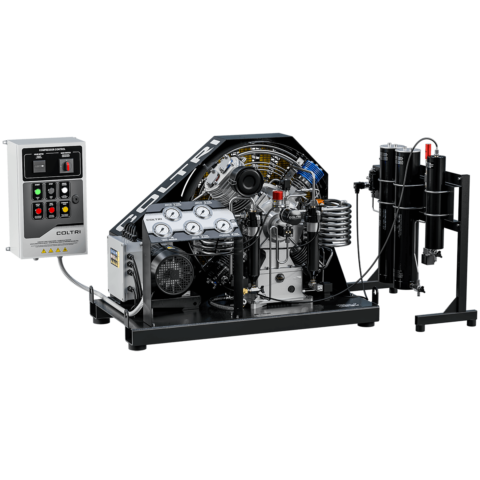

Ace I

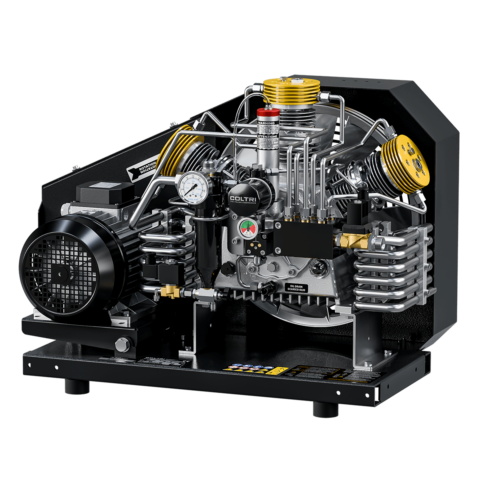

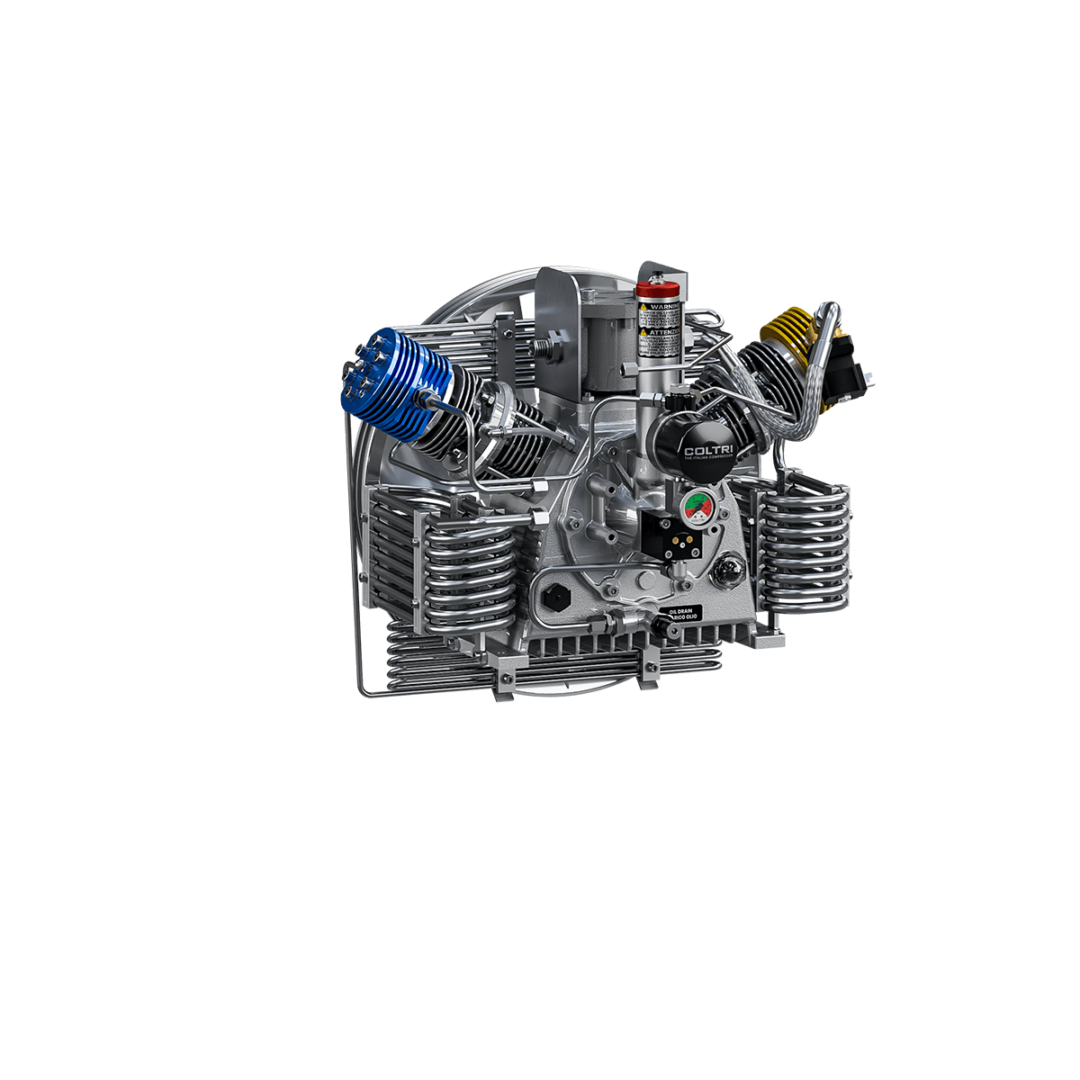

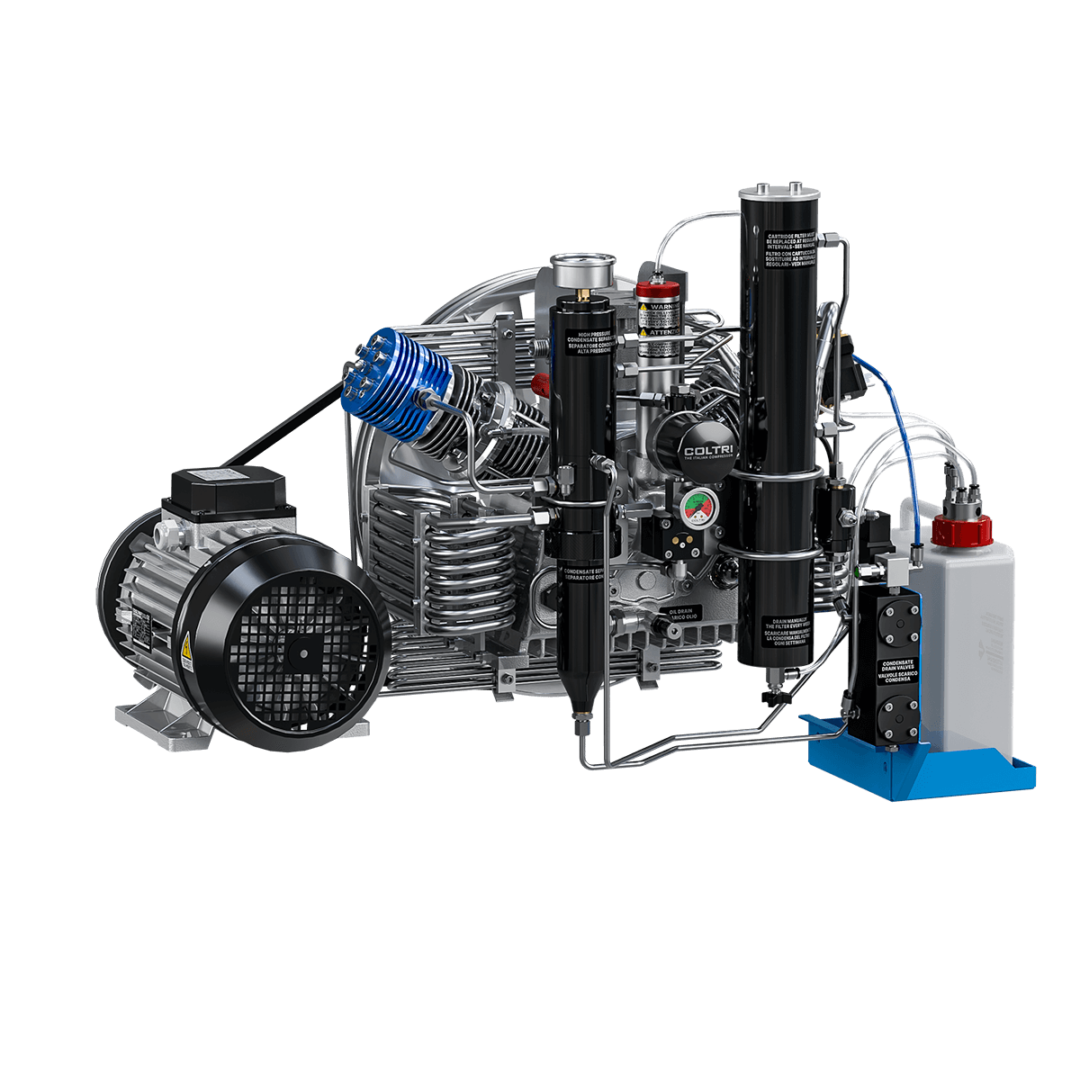

2-stage high pressure pumping unit.

- Monobloc in aluminum,

- Crankshaft in forged steel

- with forced lubrication on 2nd and 3rd stage cylinders by gear pump

- Oil filtration.

- Oversized interstage cooling pipes

- Double final separator

- Forged aluminum connecting rods

- Main roller bearings

- Roller connecting rod bearings

- 2nd stage cylinder in aluminum with hard nicasil coating

- 2nd and 3rd stage slide guide cylinders in aluminum with hard nicasil coating

- 3rd stage cylinder in special treated steel.

- Stainless steel intake and exhaust valves

- Interstage cooling pipes in stainless steel

- Separator after the 2nd and 3rd stage

- Safety valves after each stage

- Oil level sensor

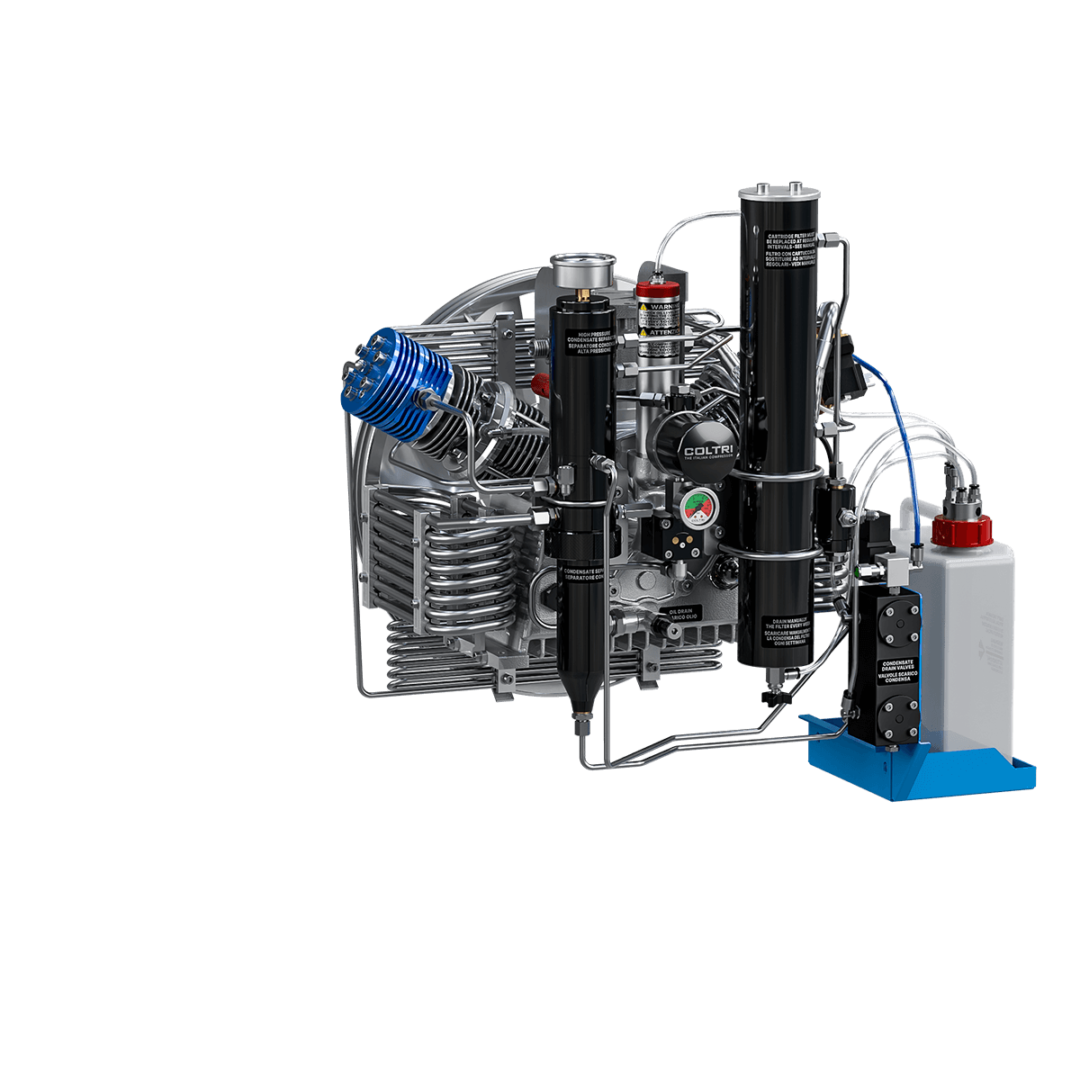

The purity of the air is achieved.

The Maxifilter purification system enables reliable treatment of breathing air and technical gases according to DIN EN 12021¹ when using original filter cartridges. Placed after the last compressor separator and before the pressure maintenance valve, it has the separator after the 2nd and 3rd stage to create a first, fundamental barrier against humidity. The filtering capacity with inlet air at 20 ° C and 200bar is 620 m³.

Electric motor

One of the fundamental parts of the compressor: the motor transfers the motion to the pumping unit through the belt. The 4 to 5 three-phase electric motor is available on this model, 5 kW.

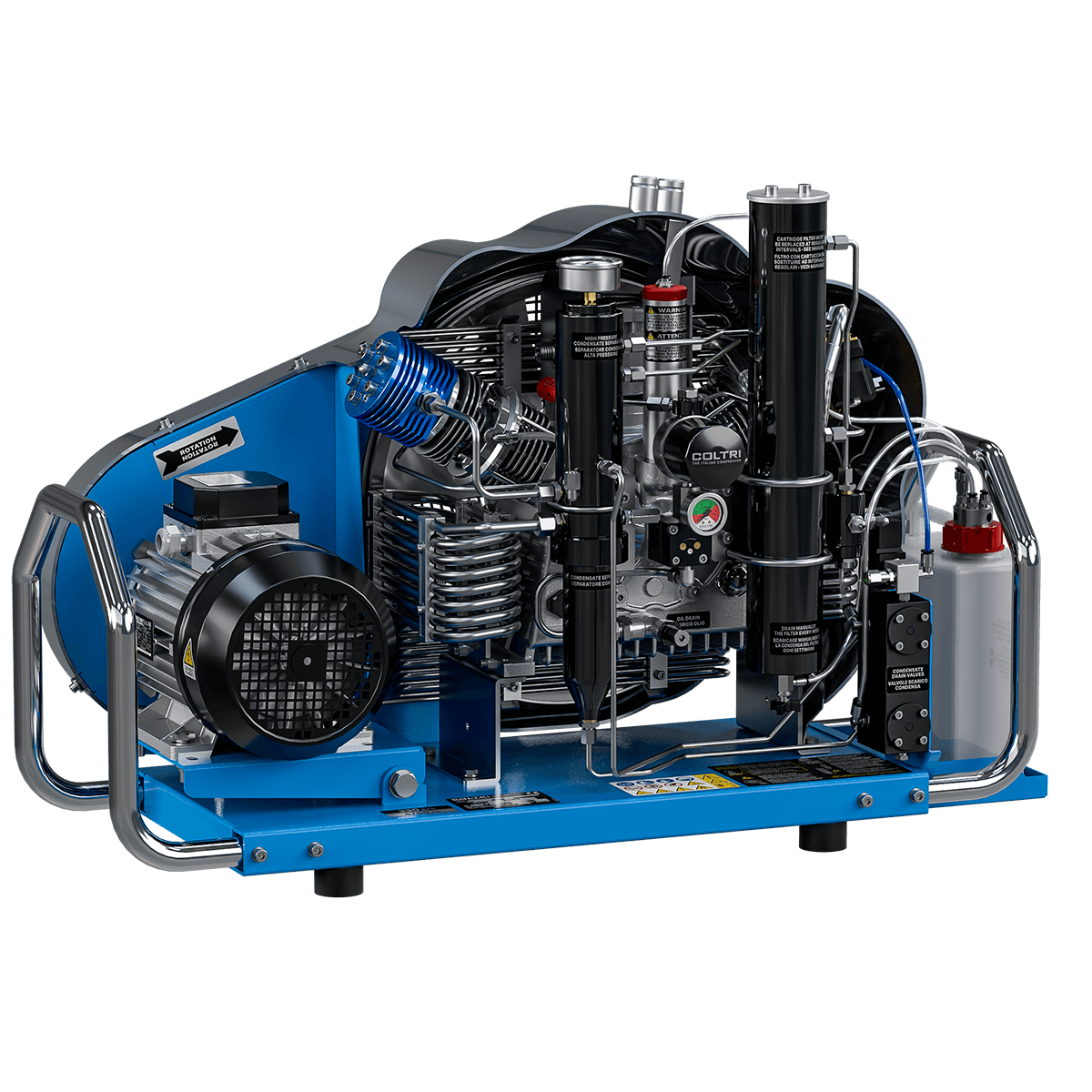

Chassis

Essential and compact, this frame is designed to facilitate portability. The tilting motor-holder plate guarantees the constant tension of the V-belt. The protective casing in thermo-formed material conveys the cooling air on the cylinders and on the inter-stage pipes. This guarantees a high compression efficiency.

Standard equipment

Oil pump with pressure gauge

Pressure maintenance valve

Carrying handles

Input pressure switch

Automatic condensate drain with autostop

Frame color Blue RAL 5015

Technical data

Type of gas

Breathing Air (EN 12021) – Helium – Nitrogen – Argon

Intake pressure

2 to 8 bar

Nominal pressure

250 bar / 330 bar

Working pressure

232 bar / 300 bar

Max working pressure

420 bar

Permissible ambient temperature range

-10° C ÷ +40° C

Permissible altitude

0 ÷ 1.500 m SLM

Max permissible tilt

15°

Design

Basic

Operating voltage, standard

400 V; 50 Hz

Other operating voltage

On three-phase electric motor at 60Hz the power (kW / Hp) increases by 20%.230 V, 50 Hz / 440 V, 60 Hz / 230 V, 60 Hz

Oil

Synthetic Coltri Oil ST 755

Oil change interval

1 year / 1,000 h

Frame

Steel thickness 1.5 mm – color Blue RAL 5015 – Powder coating – scratch-resistant

Compressor

Charging rate

4 KW

From 28,5 l/min to 235 l/min

From 1.71 m3/h to 14.1 m3/h

From 1 CFM to 8.3 CFM

5,5 KW

From 41 l/min to 350 l/min

From 2.5 m3/h to 21 m3/h

From 1.4 CFM to 12.3 CFM

Purification system

Maxifilter

Cooling air flow, min.

4 KW

1.960 m3/h

5,5 KW

1.960 m3/h

Weight

Standard model. Weight and dimensions may vary depending on accessories.4 KW

105 kg

231 lb

5,5 KW

105 kg

231 lb

Dimensions

(W x D x H)105 x 46 x 70 cm

41.3 x 18.1 x 27.6 in

Motor

Power

4 KW

4 kW

5.5 Hp

5,5 KW

5,5 kW

7.5 Hp

Type

4 KW

Three-phase electric

5,5 KW

Three-phase electric

Operating voltage/frequency

Different voltage / frequency available on request.4 KW

400 V, 50 Hz

5,5 KW

400 V, 50 Hz

Rated current

4 KW

9.7 A

5,5 KW

12.6 A

Speed (RPM)

4 KW

2.840

5,5 KW

2.840

Protection class

IP55 (TEFC)

The available models of Ace I

(Non-standard models available upon request)