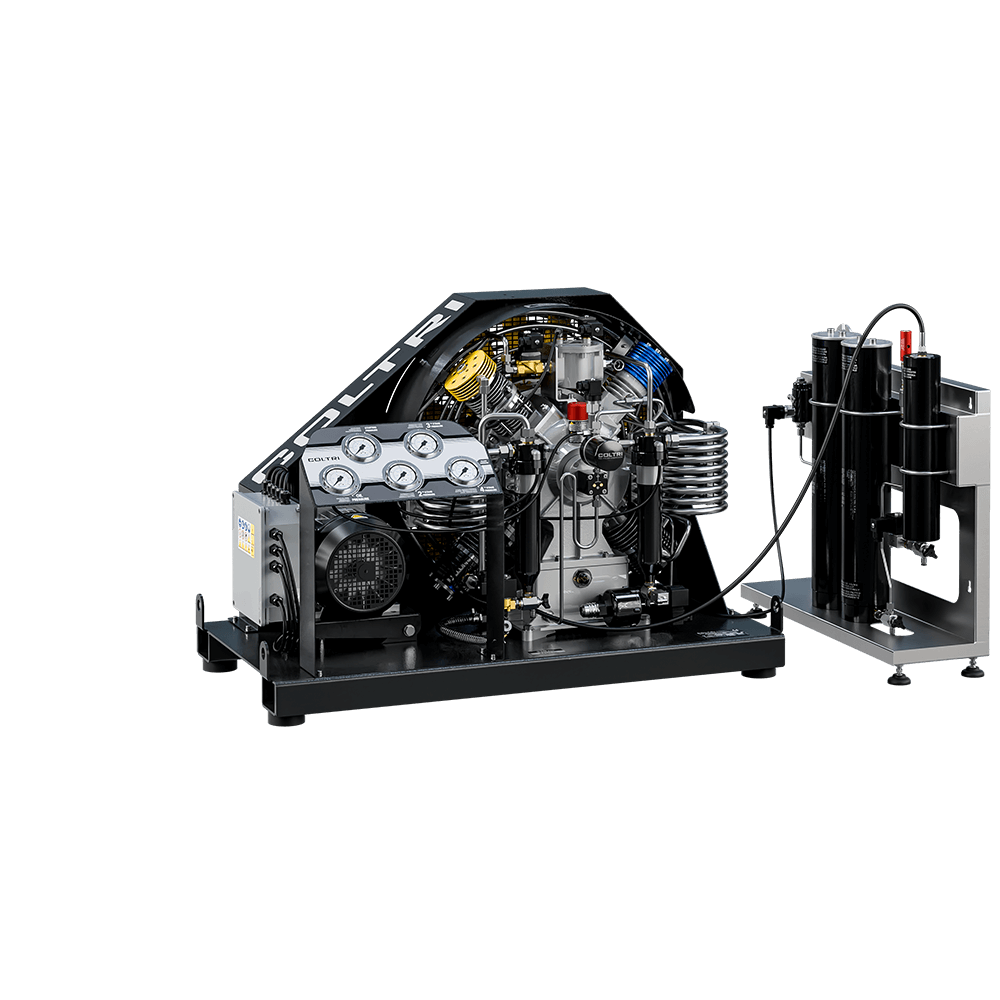

Ace VII Zero Loss

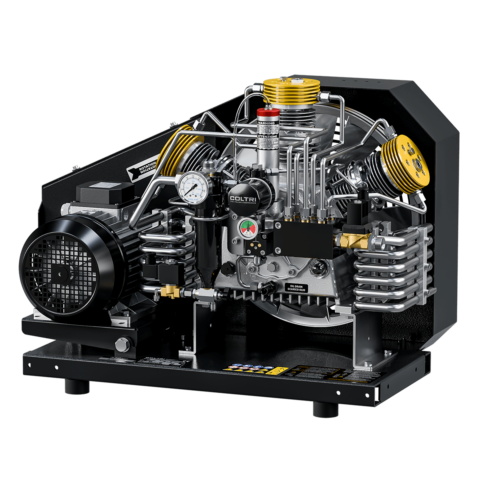

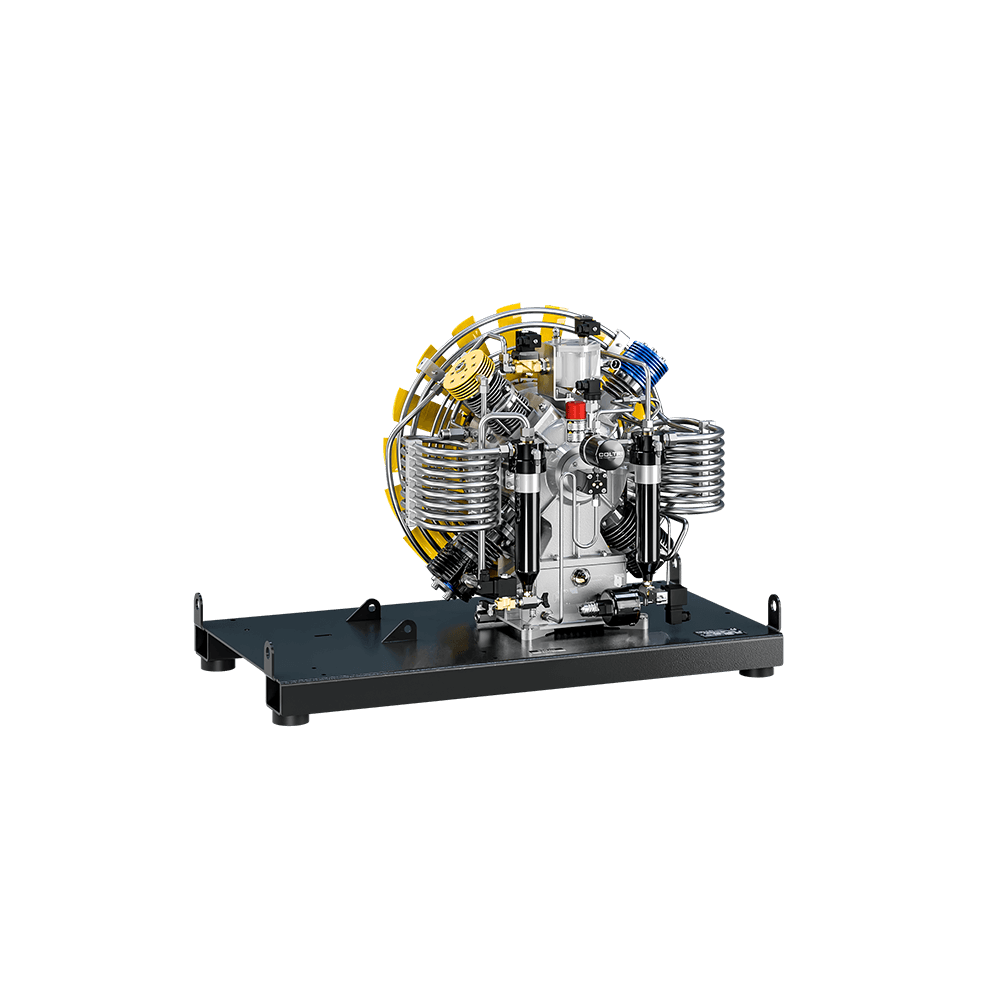

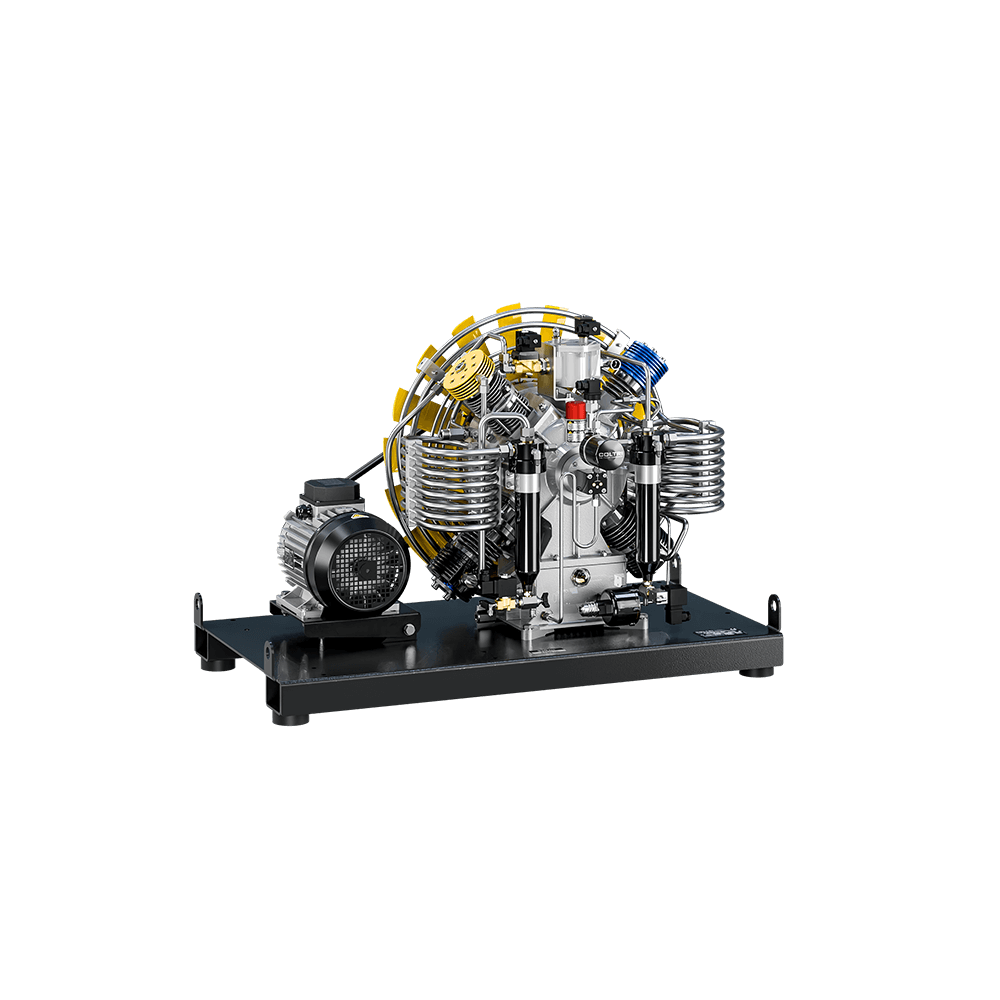

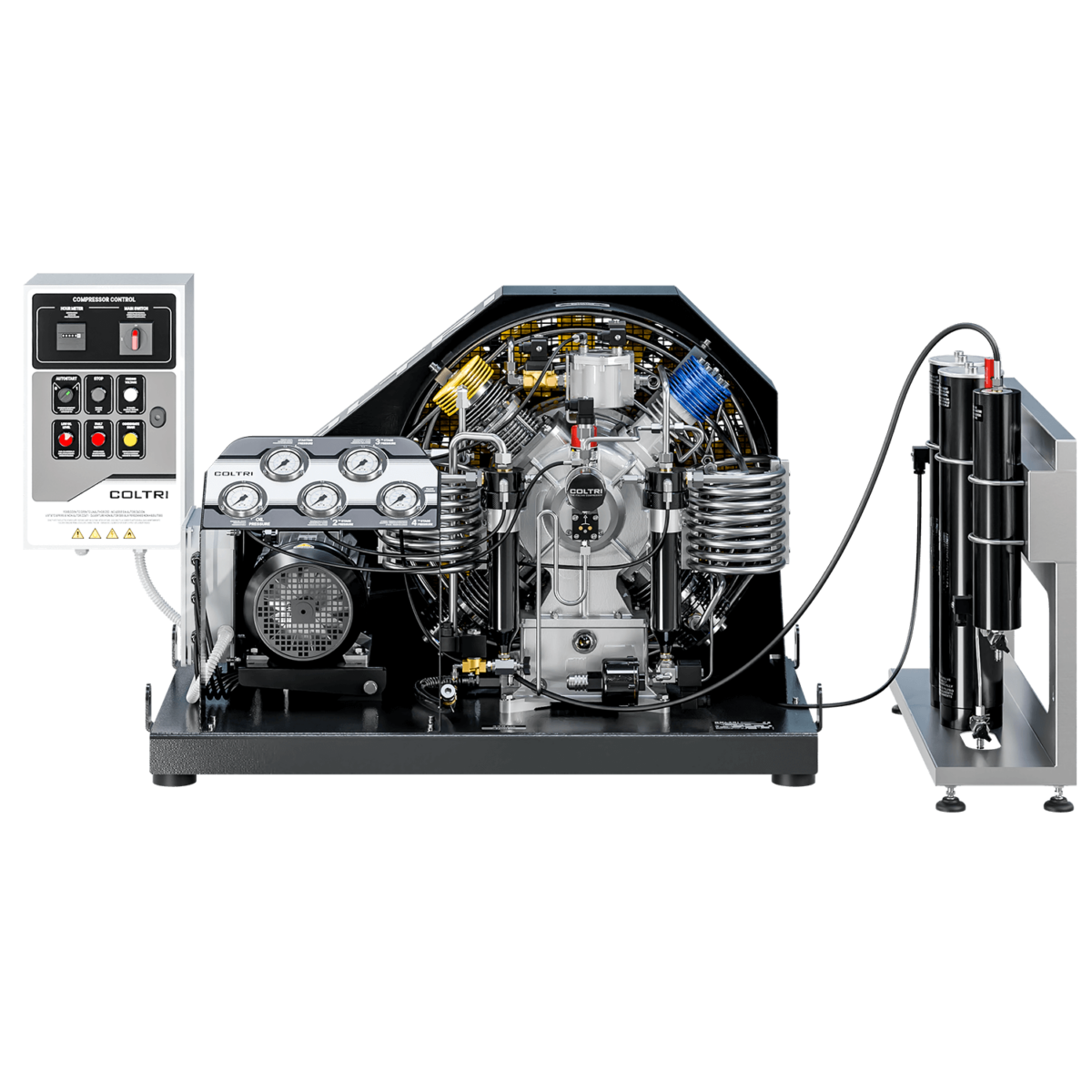

4-stage pumping unit with gas recovery

- 4-stage high pressure pumping unit.

- Single lever in aluminum,

- Crankshaft in forged steel

- forced lubrication on the 4th stage cylinder by gear pump

- Oil filtration

- Aluminum connecting rods

- Main roller bearings

- Roller connecting rod bearings

- 2nd and 3rd stage cylinders in special cast iron

- 4th stage cylinder in special treated steel.

- Stainless steel intake and exhaust valves

- Interstage cooling pipes in stainless steel

- Separator after the 2nd, 3rd and 4th stage

- Safety valves after each stage

- Oil level sensor

- With service stage that recovers the gas that leaks towards the monoblock and reintroduces it in the 2nd stage

Electric motor

One of the fundamental parts of the compressor: the motor transfers the motion to the pumping unit through the belt. The 5.5 three-phase electric motor is available on this model. kW.

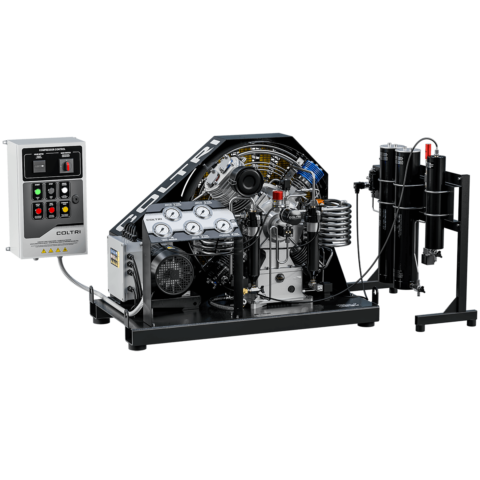

Stand-alone filter system with Hyperfilter

The filter system, with activated carbon cartridge, is mounted on a stand-alone stand and includes:

- Safety valve (variable according to customer’s request)

- Pressure maintenance valve

- External Hyperfilter and separator kit

- Leg kit

- Automatic condensate drain. Removes water from the intermediate separator and the final separator automatically during operation (every 7 minutes).

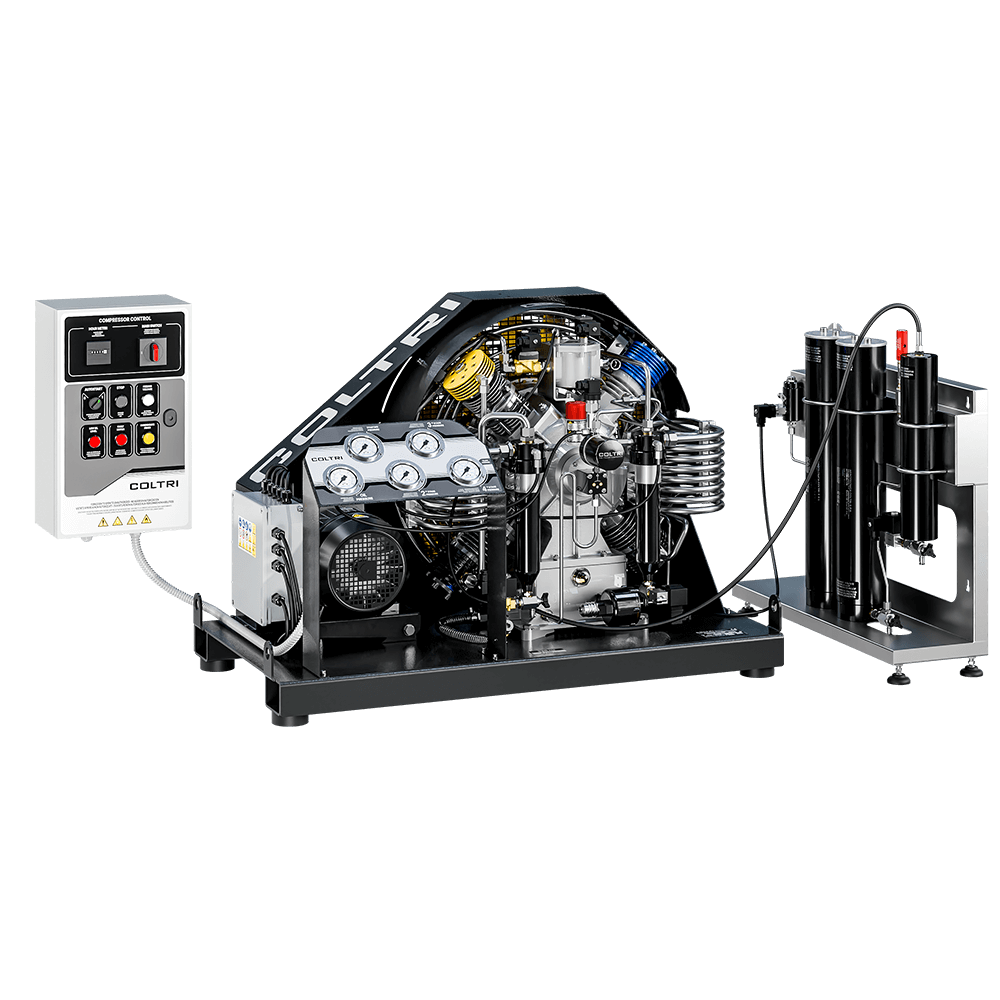

Compressor control and automatic condensate drainage system

- Motor protection switch.

- Autostop + Autostart.

- Drainage of the separator between individual stages during compressor operation (standard drainage interval every 15 minutes for a period of 6 seconds).

- Interstage pressure gauges display the working pressure for the individual compression stages. This pressure information allows you to check the tightness of the valves (inlet and outlet) of each stage and to quickly identify potential sources of failure.

Interstage pressure gauges are mounted in the compressor frame.

Standard equipment

Double PED certified Hyperfilter filter system

Condensate separation system

Frame color Black RAL 9005

Technical data

Type of gas

Air – Helium – Nitrogen – Argon

Intake pressure

2 to 5 bar

Nominal pressure

250 bar / 330 bar

Working pressure

232 bar / 300 bar

Max working pressure

420 bar

Permissible ambient temperature range

-10° C ÷ +40° C

Permissible altitude

0 ÷ 1.500 m SLM

Max permissible tilt

15°

Design

Cabinet insonorizzato con fonoassorbente

Operating voltage, standard

400 V, 50 Hz

Other operating voltage

On three-phase electric motor at 60Hz the power (kW / Hp) increases by 20%.230 V, 50 Hz / 440 V, 60 Hz / 230 V, 60 Hz

Oil

Synthetic Coltri Oil ST 755

Oil change interval

1 year / 1,000 h

Frame

Steel – Color Black RAL 9005 – Powder coating – scratch-resistant

Compressor

Charging rate

11 KW

From 250 l/min to 620 l/min

From 15 m3/h to 37 m3/h

From 8.8 CFM to 21.9 CFM

15 KW

From 280 l/min to 690 l/min

From 17 m3/h to 41.4 m3/h

From 9.9 CFM to 24.3 CFM

Purification system

2 Hyperfilter a carbone attivo

Cooling air flow, min.

11 KW

1.960 m3/h

15 KW

1.960 m3/h

Weight

Standard model. Weight and dimensions may vary depending on accessories.11 KW

225 kg

496 lb

15 KW

225 kg

495 lb

Dimensions

(W x D x H)115 x 60 x 79,6 cm

45.3 x 23.6 x 31.3 in

Motor

Power

11 KW

11 kW

15 Hp

15 KW

15 kW

20 Hp

Type

11 KW

Three-phase electric

15 KW

Three-phase electric

Operating voltage/frequency

Different voltage / frequency available on request.11 KW

400 V, 50 Hz

15 KW

400 V, 50 Hz

Rated current

11 KW

23 A

15 KW

31 A

Speed (RPM)

11 KW

2.910

15 KW

2.920

Protection class

IP55 (TEFC)

Available models of Ace VI Zero Loss

(Non-standard models available upon request)