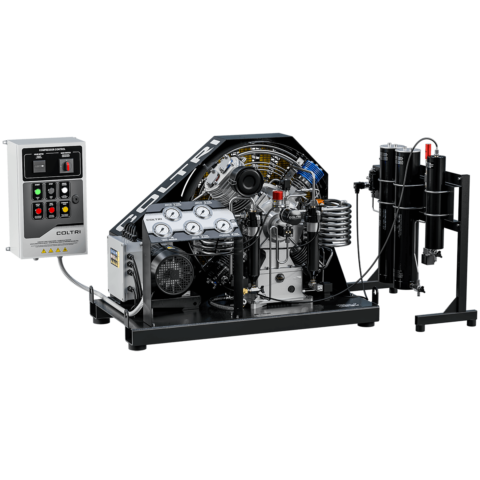

H2 Booster HD

Charging is fast, the future is “greener.”

A green breakthrough in vehicle charging systems. Designed to recharge hydrogen-powered cars efficiently and safely. Its ability to operate at high pressure ensures rapid refueling, significantly reducing waiting time for users. Using hydrogen as an energy source makes it an environmentally friendly option, helping to reduce greenhouse gas emissions and promote sustainable mobility. It provides a maximum operating pressure of 360 bar with a filling capacity ranging from 220 and 620 l/min.

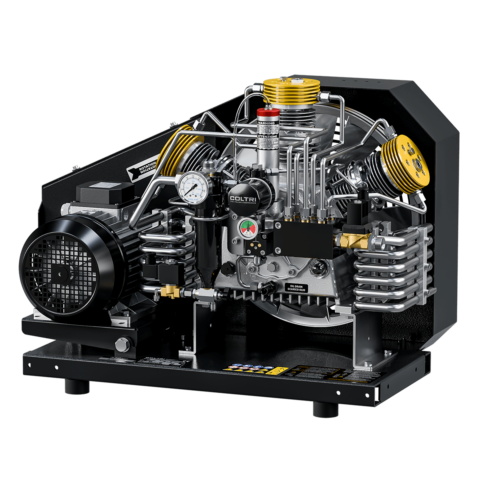

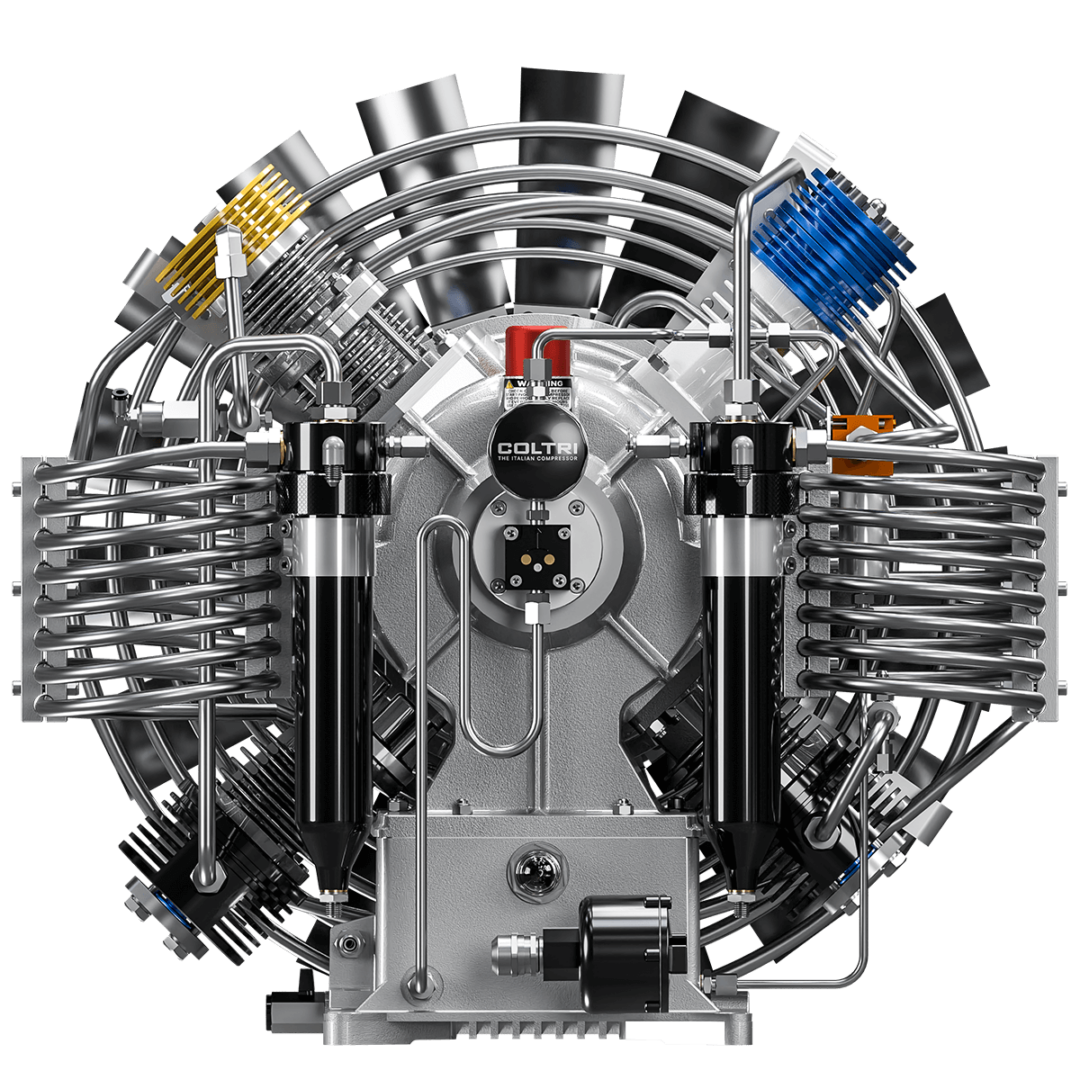

4-stage high pressure pumping unit for hydrogen.

- Monobloc in aluminum

- Forged steel crankshaft

- Forced lubrication with low-pressure gear pump

- Input filter

- Tubes, fittings and nuts made of AISI 316 stainless steel

- Pressure maintenance and control valve after final air filter purification

- High-pressure final condensate separator

- Safety pressure switch after each compression stage

- Special cast iron cylinders with low roughness lapping

- Forged aluminum connecting rods

- High-flow second- and third-stage valves

- Heavy-duty roller bearings

- Hardened steel fourth stage with 6 segments made of special cast iron

- Second and third stages with thrust pads to eliminate lateral forces on the pistons

- Monobloc in aluminum

- Forged steel crankshaft

- Forced lubrication with low-pressure gear pump

- Input filter

- Tubes, fittings and nuts made of AISI 316 stainless steel

- Pressure maintenance and control valve after final air filter purification

- High-pressure final condensate separator

- Safety pressure switch after each compression stage

- Special cast iron cylinders with low roughness lapping

- Forged aluminum connecting rods

- High-flow second- and third-stage valves

- Heavy-duty roller bearings

- Hardened steel fourth stage with 6 segments made of special cast iron

- Second and third stages with thrust pads to eliminate lateral forces on the pistons

Standard equipment

Intake filter

Dual Hyperfilter filter system with activated carbon

4.5 m filling hose

Gas exhaust chimney

Frame color RAL 7035 / RAL 7016

Technical data

Type of gas

Hydrogen

Intake pressure

2 to 6 bar

Nominal pressure

360 bar

Working pressure

300 – 360 bar

Max working pressure

360 bar

Permissible ambient temperature range

-10° C ÷ +40° C

Permissible altitude

0 ÷ 1.500 m SLM

Max permissible tilt

6°

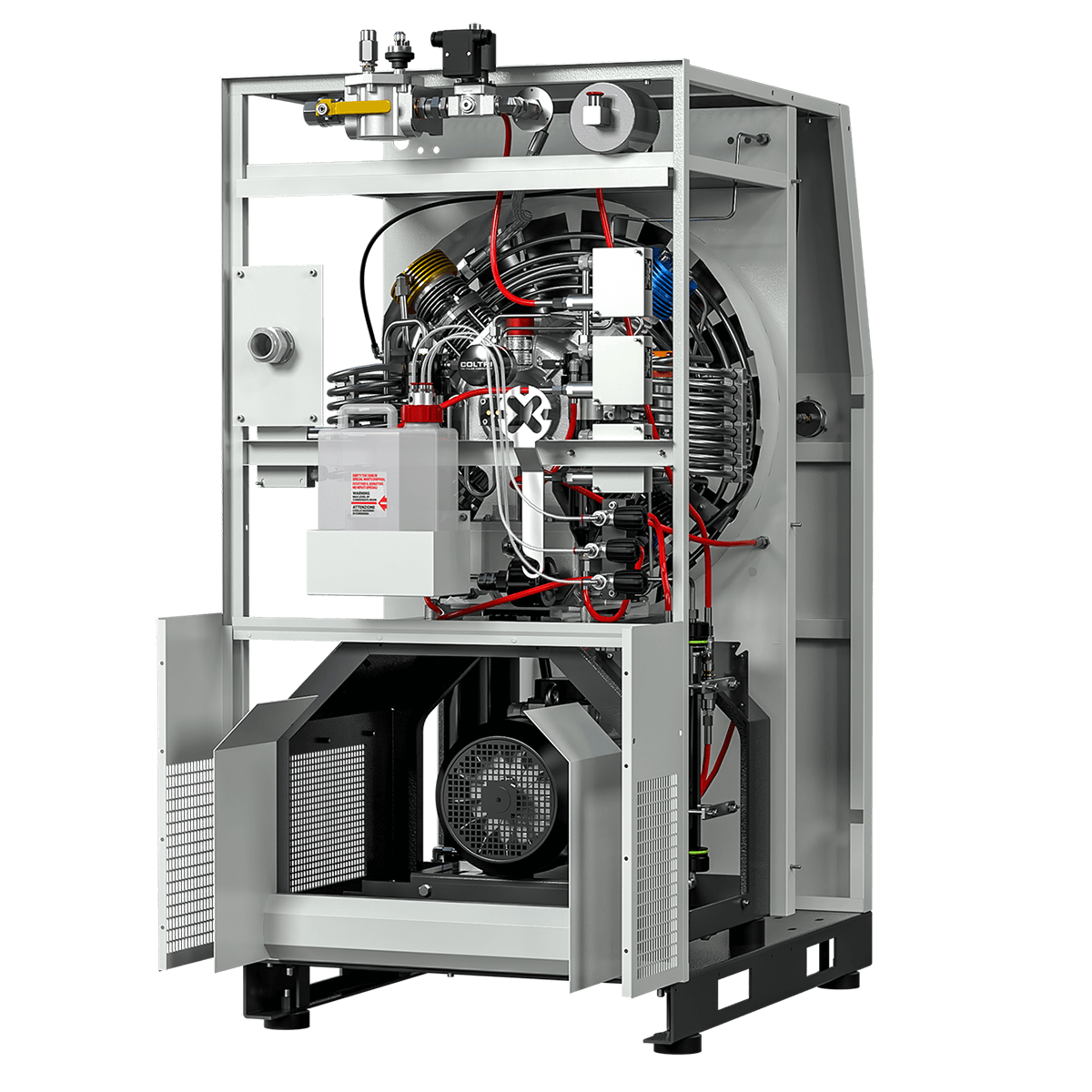

Design

Cabinet insonorizzato

Operating voltage, standard

400 V, 50 Hz

Other operating voltage

On three-phase electric motor at 60Hz the power (kW / Hp) increases by 20%.230 V, 50 Hz / 230 V, 60 Hz / 400 V, 60 Hz

Oil

Synthetic Coltri Oil ST 755

Oil change interval

1 year / 1,000 h

Frame

Steel – color RAL 7035 – RAL 7016 Powder coating – scratch resistant

Noise

LpA 67 dB

Compressor

Charging rate

9,2 KW

From 220 l/min to 560 l/min

From 13.5 m3/h to 33.5 m3/h

From 8 CFM to 19.7 CFM

11 KW

From 250 l/min to 620 l/min

From 15 m3/h to 37.2 m3/h

From 8.8 CFM to 21.9 CFM

Purification system

Doppio Hyperfilter con carbone attivo

Cooling air flow, min.

9,2 KW

930 m3/h

11 KW

1.240 m3/h

Weight

Standard model. Weight and dimensions may vary depending on accessories.9,2 KW

420 kg

926 lb

11 KW

420 kg

926 lb

Dimensions

(W x D x H)79 x 124 x 153 cm

31.1 x 48.8 x 60.2 in

Motor

Power

9,2 KW

9,2 kW

12.3 Hp

11 KW

11 kW

15 Hp

Type

9,2 KW

Three-phase electric

11 KW

Three-phase electric

Operating voltage/frequency

Different voltage / frequency available on request.9,2 KW

400 V, 50 Hz

11 KW

400 V, 50 Hz

Rated current

9,2 KW

18.8 A

11 KW

23 A

Speed (RPM)

9,2 KW

2.880

11 KW

3.500

Protection class

IP55

Available models of H2 Booster HD

(Non-standard models available upon request)