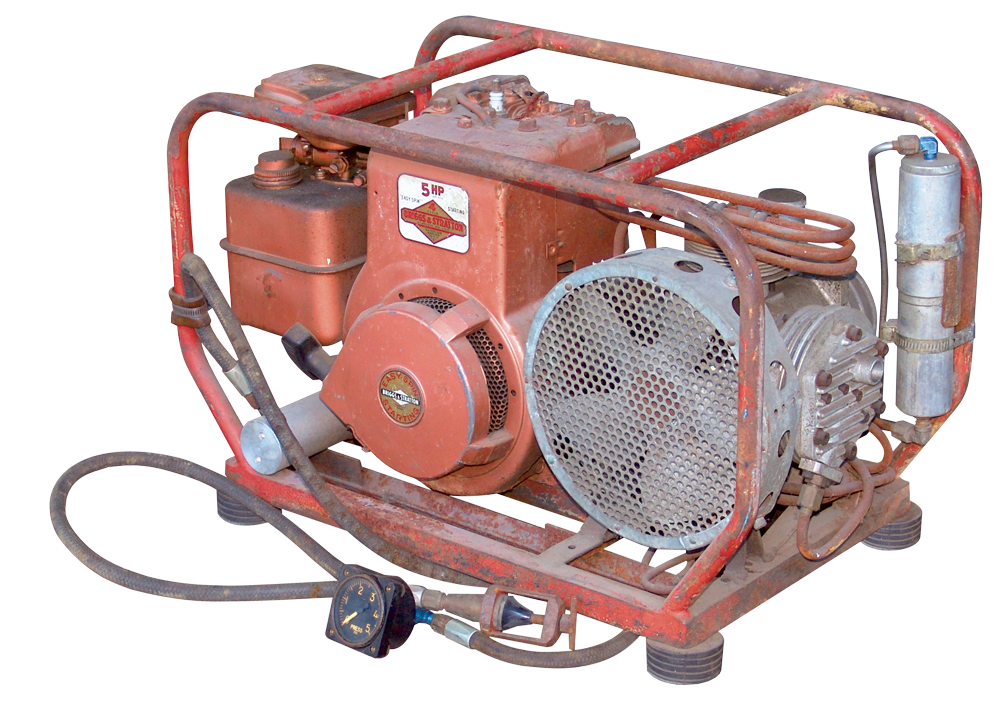

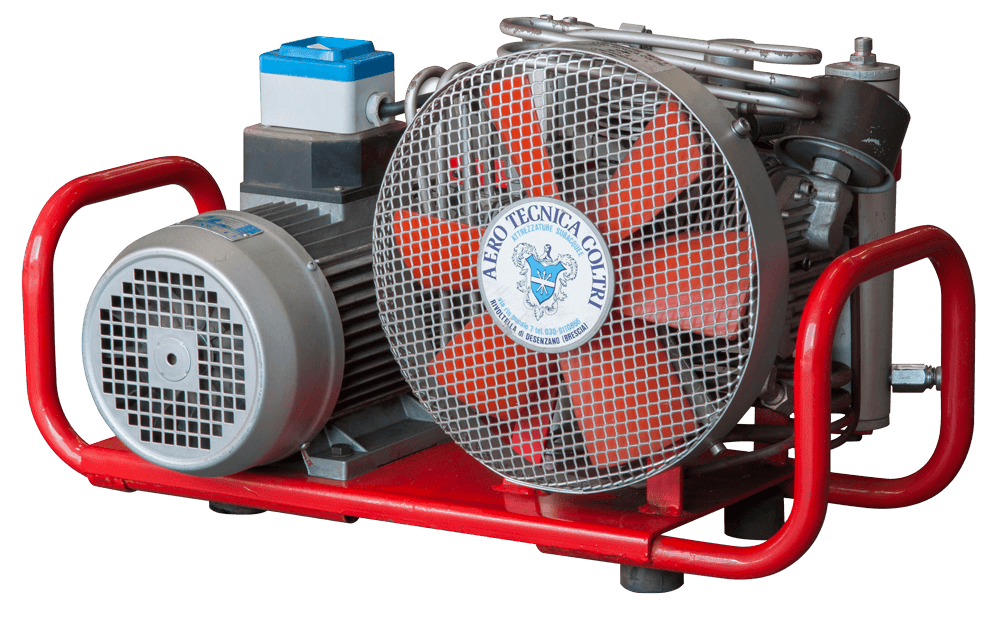

Breathing air compressors,

strictly Made in Italy.

Play Video

60 years in the production of Made in Italy compressors.

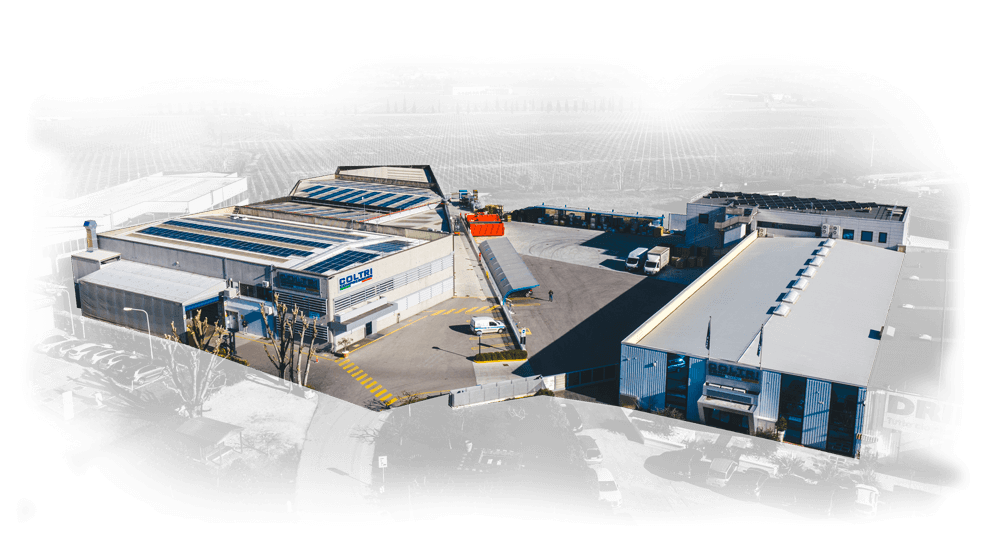

Coltri Compressors was founded in the 1960s to meet the demands for support in the diving world. Our Made in Italy high-pressure breathing air compressors are the result of study and technique in our Italian workshops, where we have controlled all processes from concept to assembly for more than 60 years.

Our propensity for innovation has allowed us not to stop at diving. We have expanded our offer with products dedicated to technical gases and made professional air compressors to meet the needs of additional application sectors, without forgetting who we are, with the same vision, typically Made in Italy, oriented to quality without compromise.

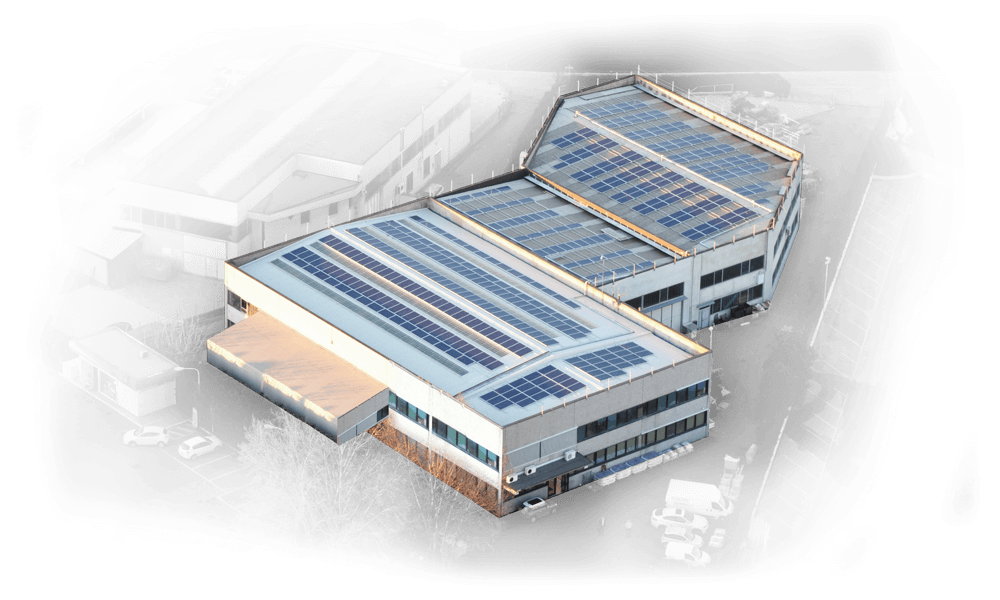

150 employees.

The request for an increase in production capacity and the presence in new application sectors allow a constant growth of this figure.

70,000 products sold.

The increasingly efficient production plants and an increase in personnel allow us to satisfy more and more customers every year.

6,000 compressors exported.

The export of breathing air compressors and technical gases accounts for nearly 70 percent of our production.

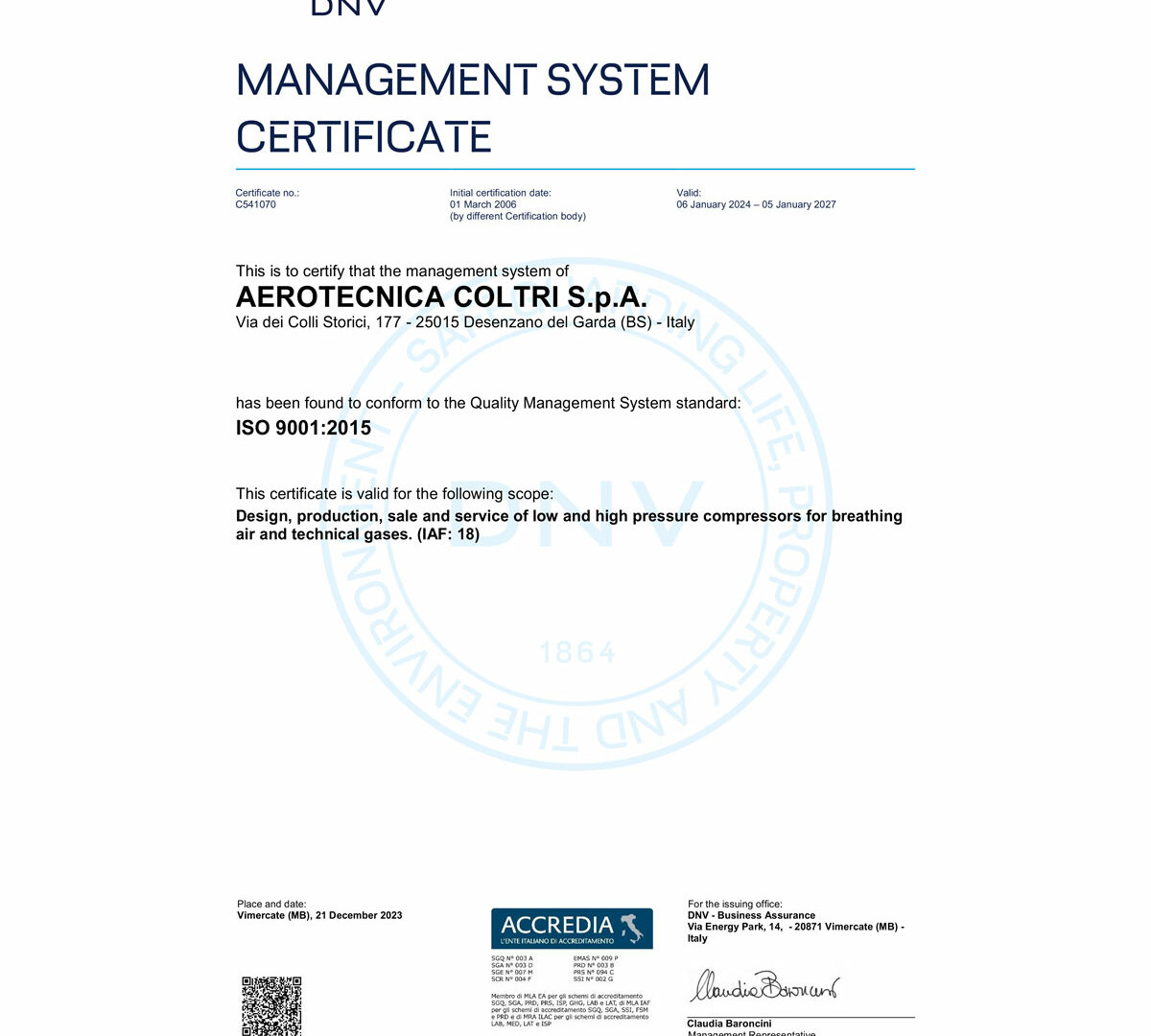

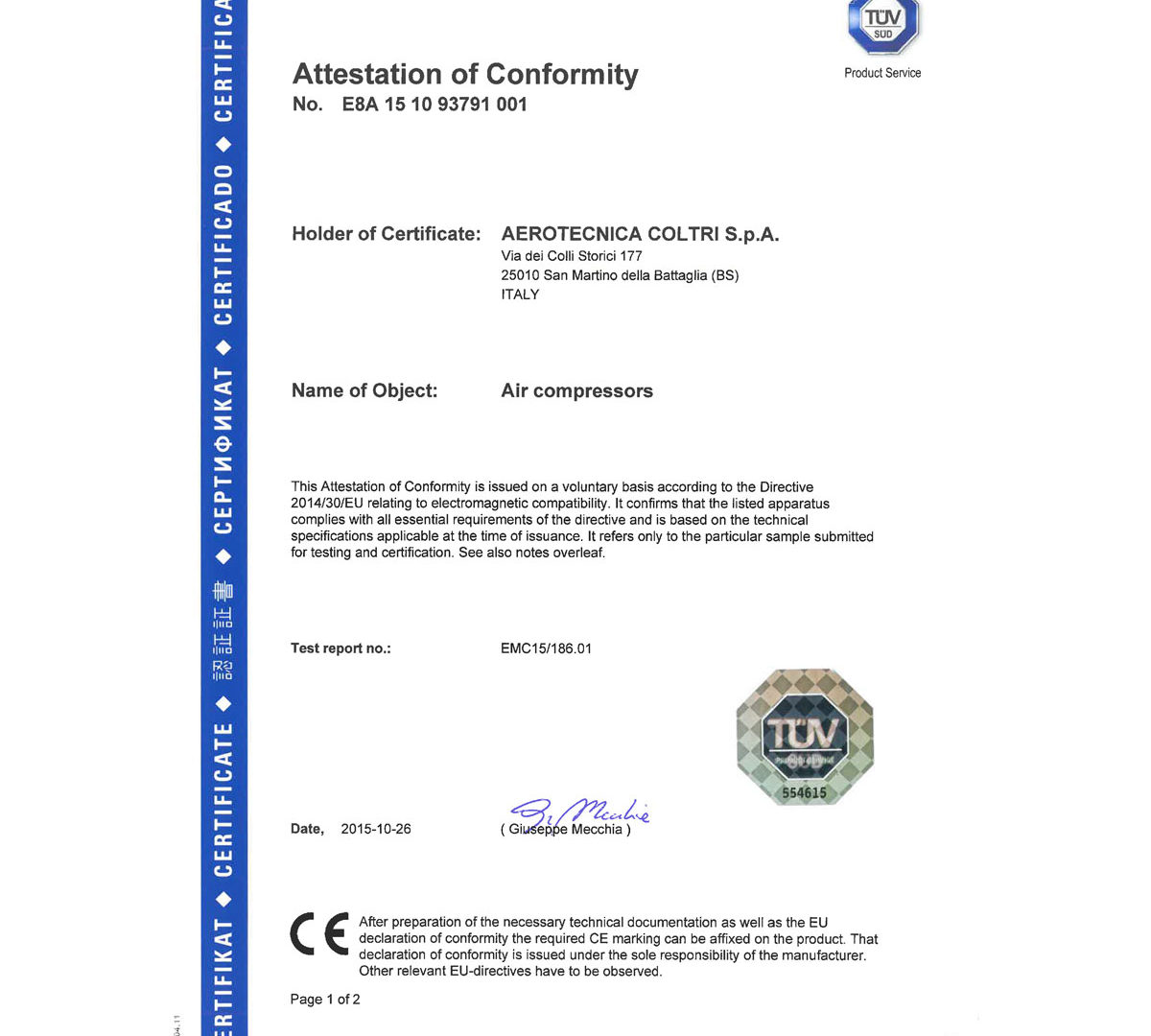

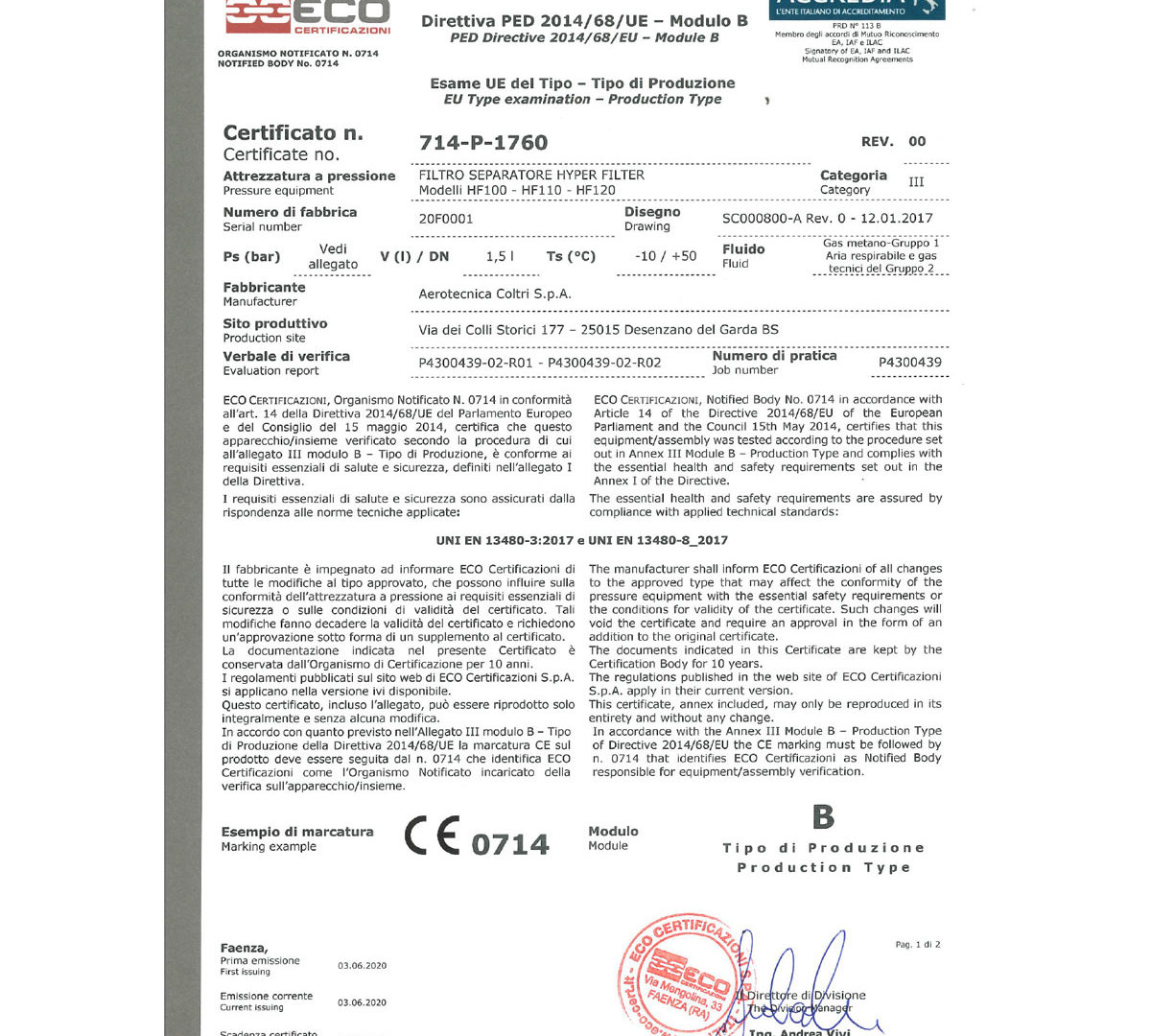

30 certifications.

Quality always comes first. Our certifications allow us to always maintain our quality standards to the maximum.

7 offices around the world.

We are close to all our customers. We have located 7 of our offices around the globe.

130 distributors.

Today our business presence covers all major countries in the world.

An industrial reality that has been able to establish itself in international markets thanks to forward-looking strategies aimed at developing production solutions that often express a marked sense of technological anticipation.

The story of Coltri Compressors.

In 60 years of activity the company has developed skills and experience such as to always be able to respond to customer needs by developing and supplying machining centers that know how to combine performance, flexibility, customization and reliability. Carlo Coltri and his father Giuseppe built for the first time a high pressure breathing air compressor to fill the cylinders used during their dives in Lake Garda. Our product is the synthesis of continuous technological development and investments in Research & Development.

1963

1982

1990

2000

2007

2015

2019

Our product is the synthesis of continuous technological development and investments in Research & Development.

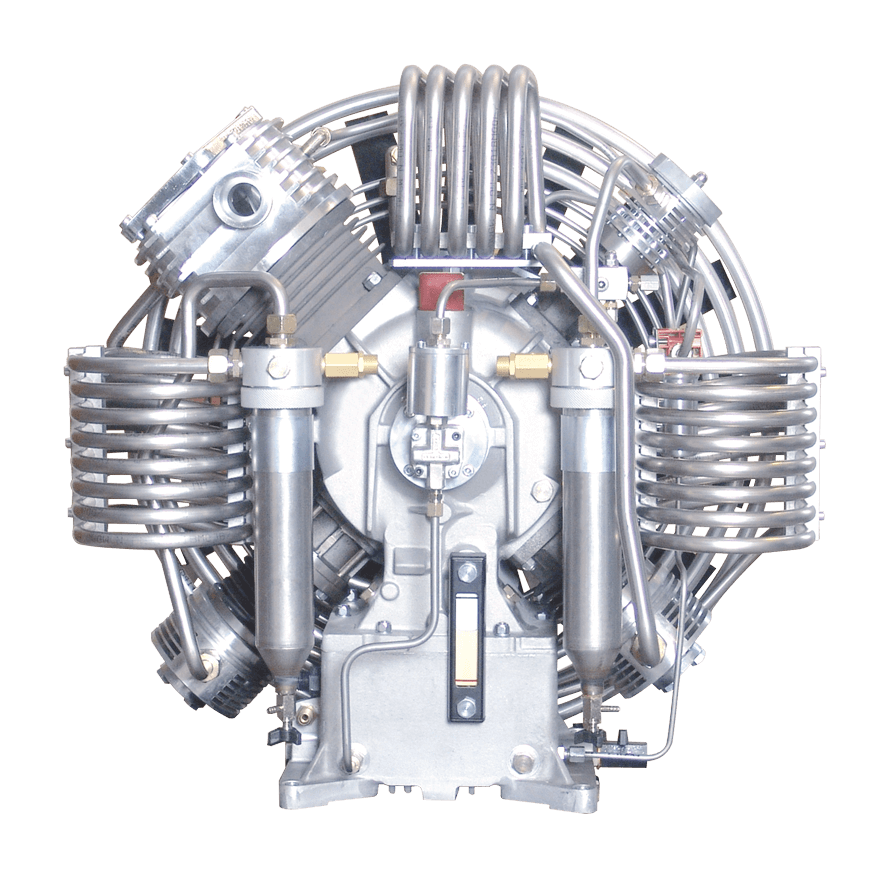

Constant evolution.

Constant evolution in the design and manufacture of Coltri Compressors has become the core element of our identity: 60 years of development have enabled us to create machinery that now sets the industry benchmark worldwide.

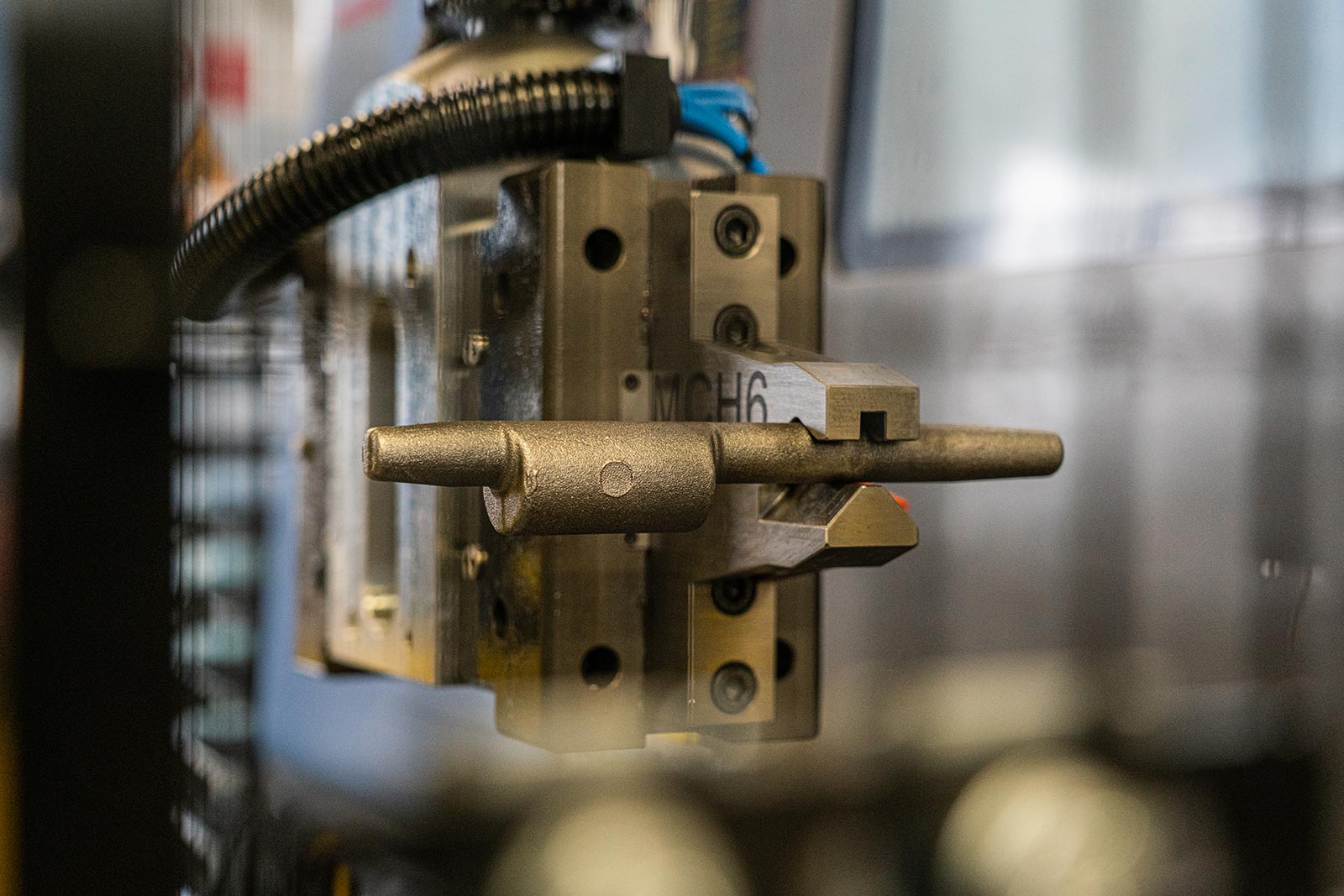

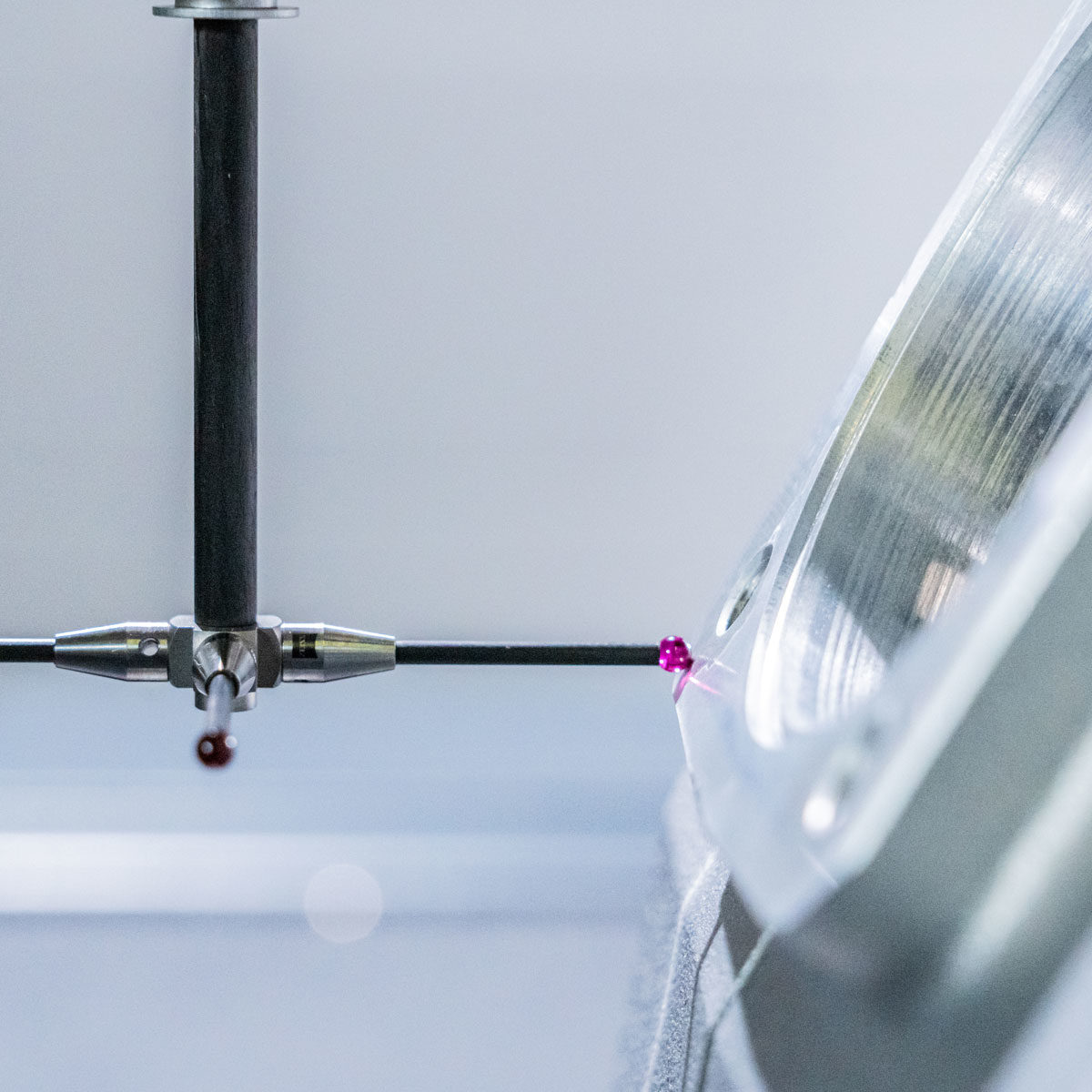

This propensity for research and development has allowed us to move from users of the most modern technical options to protagonists of the technological progress of the sector. We use all the most modern instruments, such as robots and numerically controlled machine tools, to create increasingly reliable, efficient and long-lasting products.

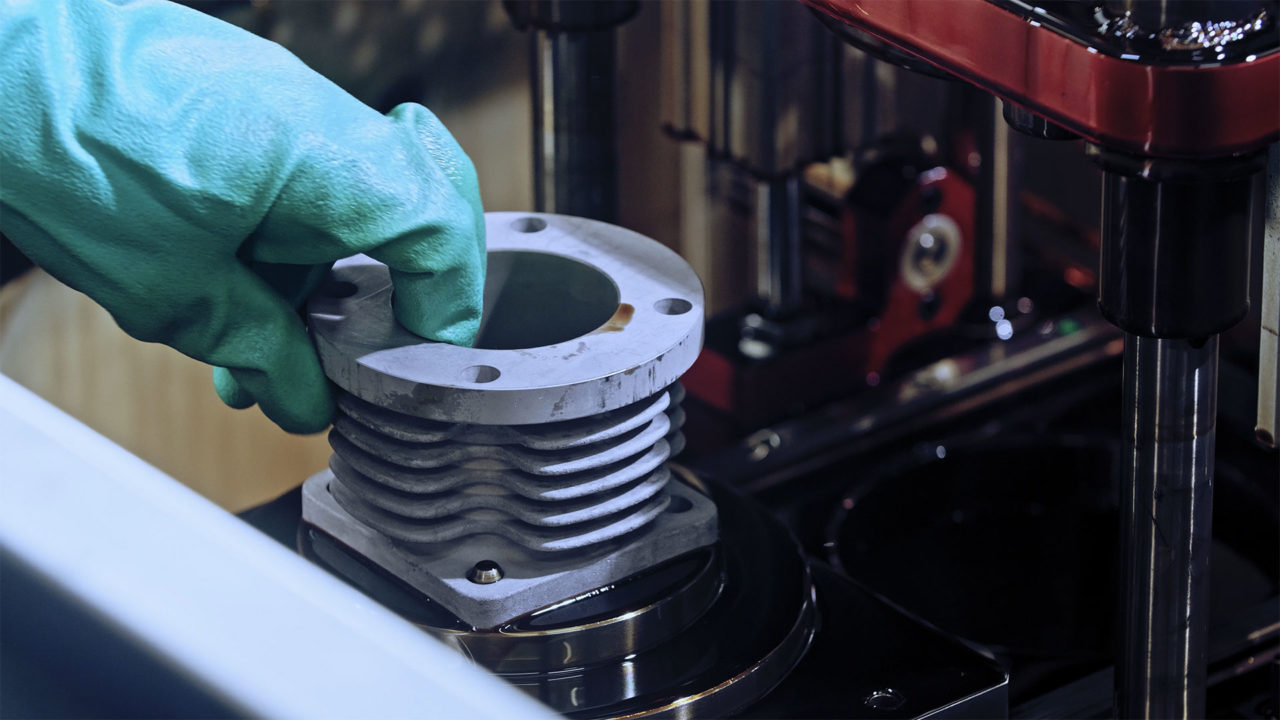

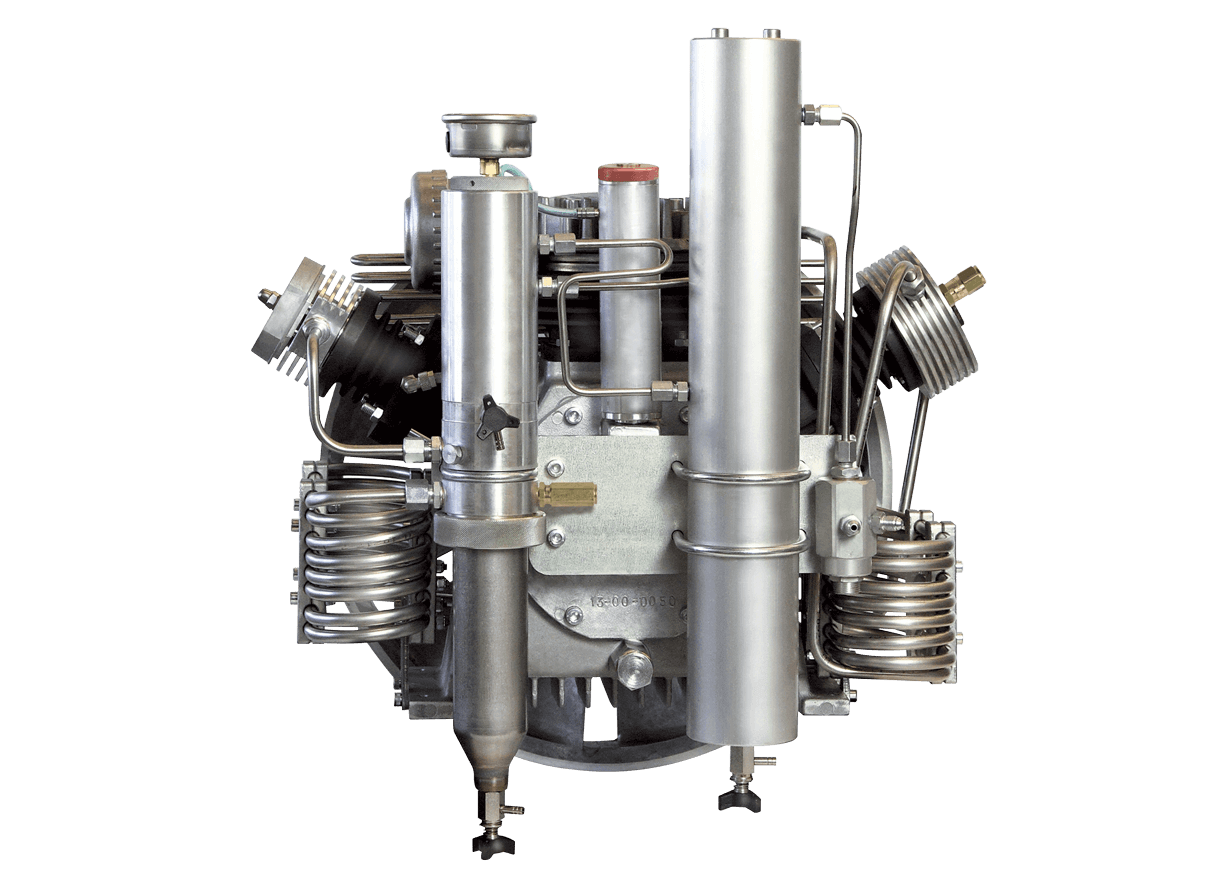

Build quality.

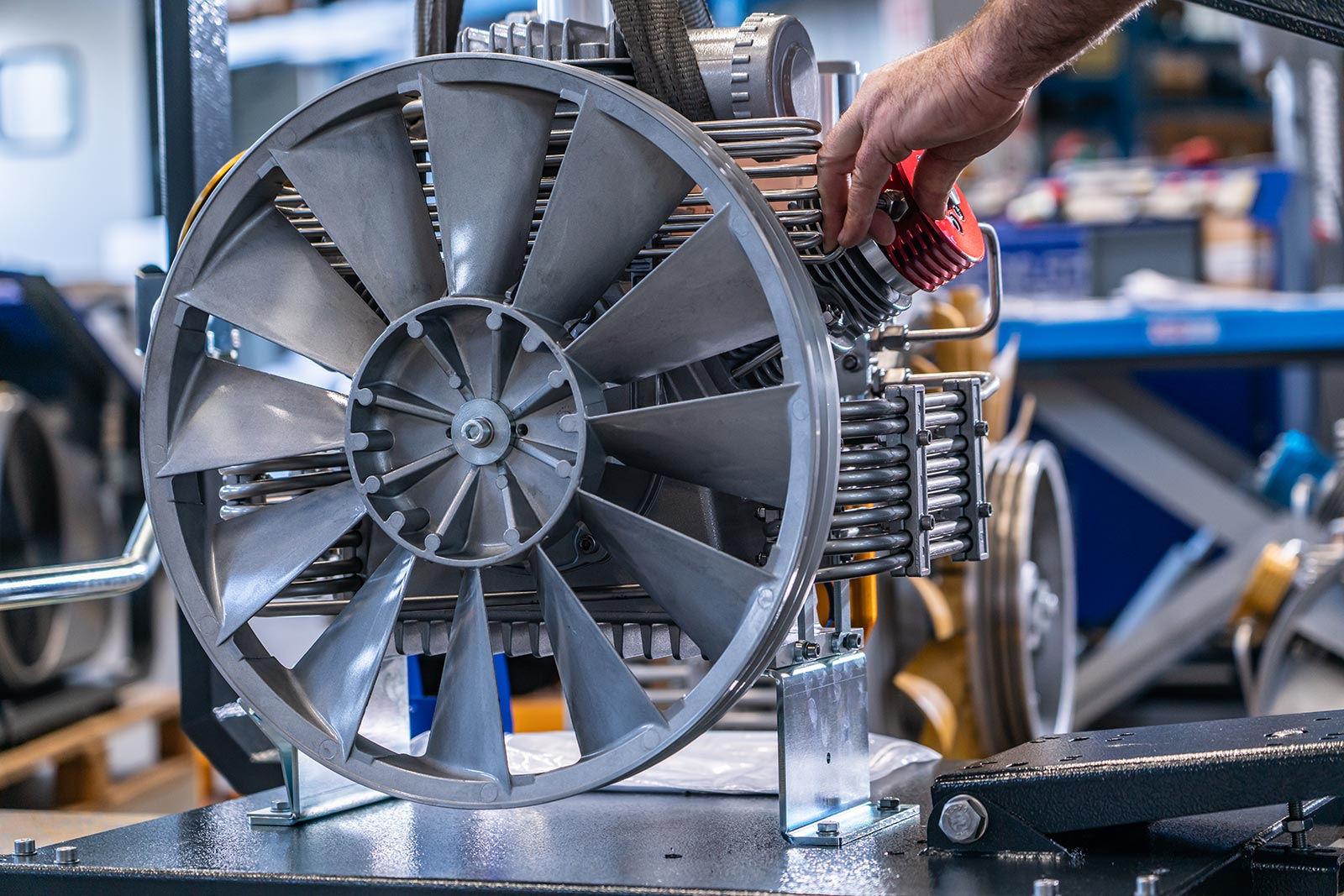

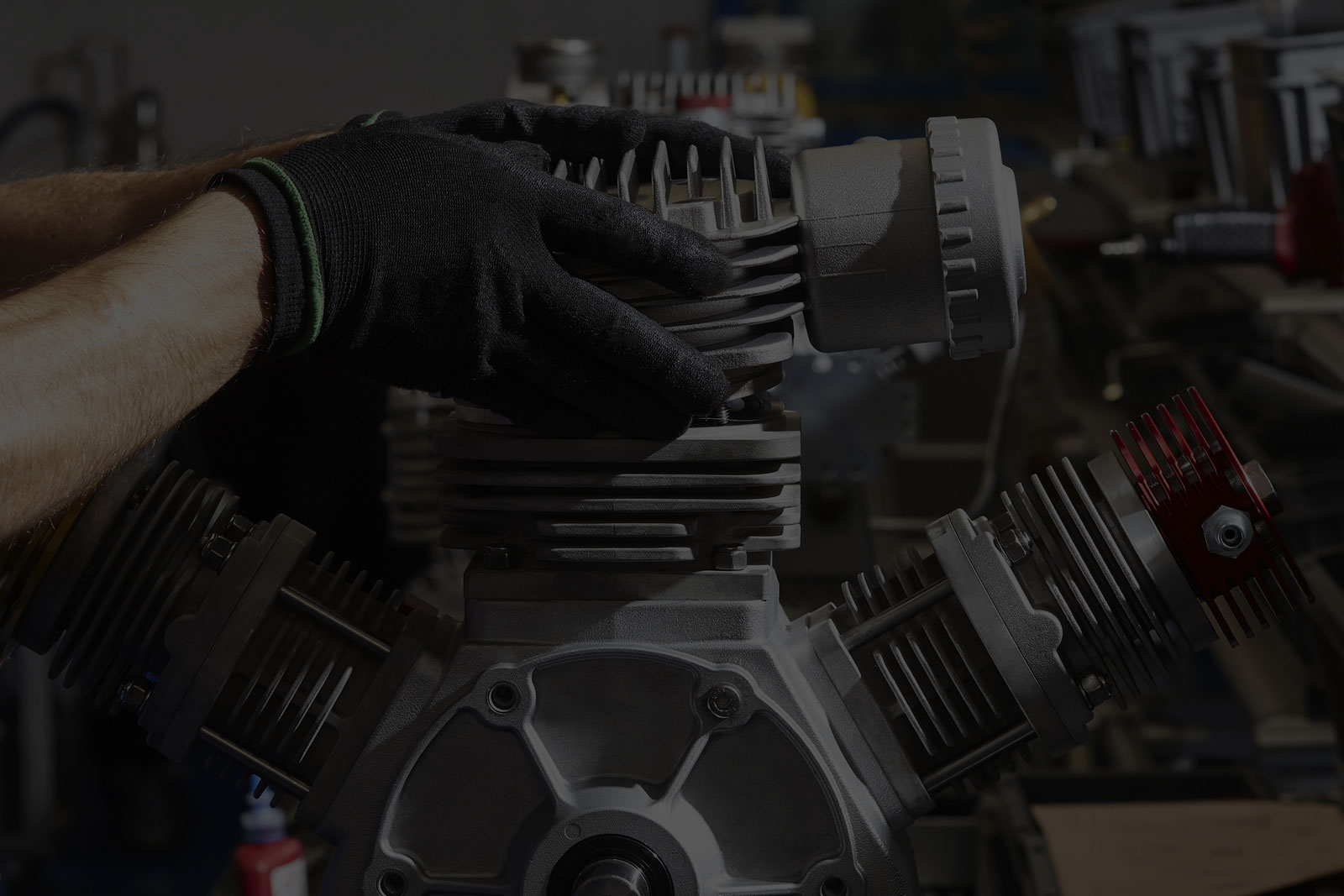

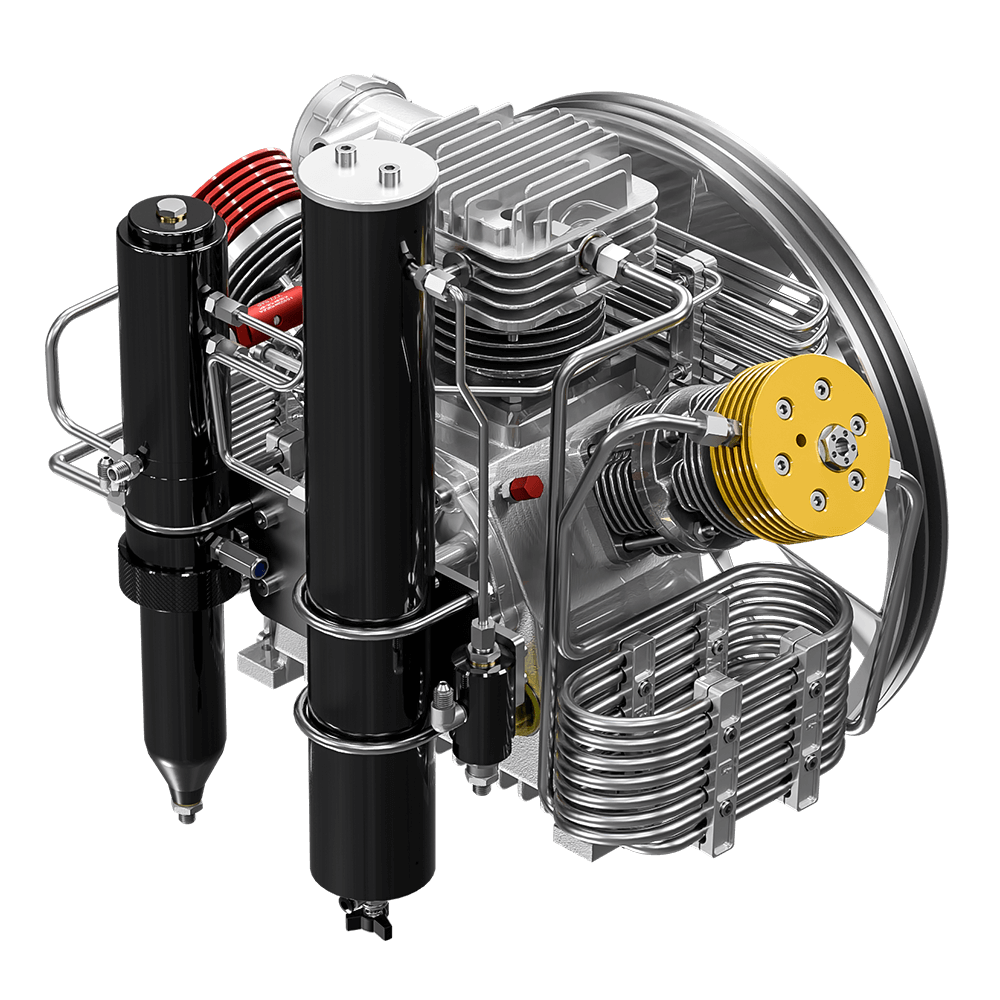

Each component of the pump units is designed and created in the Coltri Compressors workshops and is the child of careful study and extensive testing.

We assemble all our compressors

in their entirety within

of our production departments according to strict quality standards.

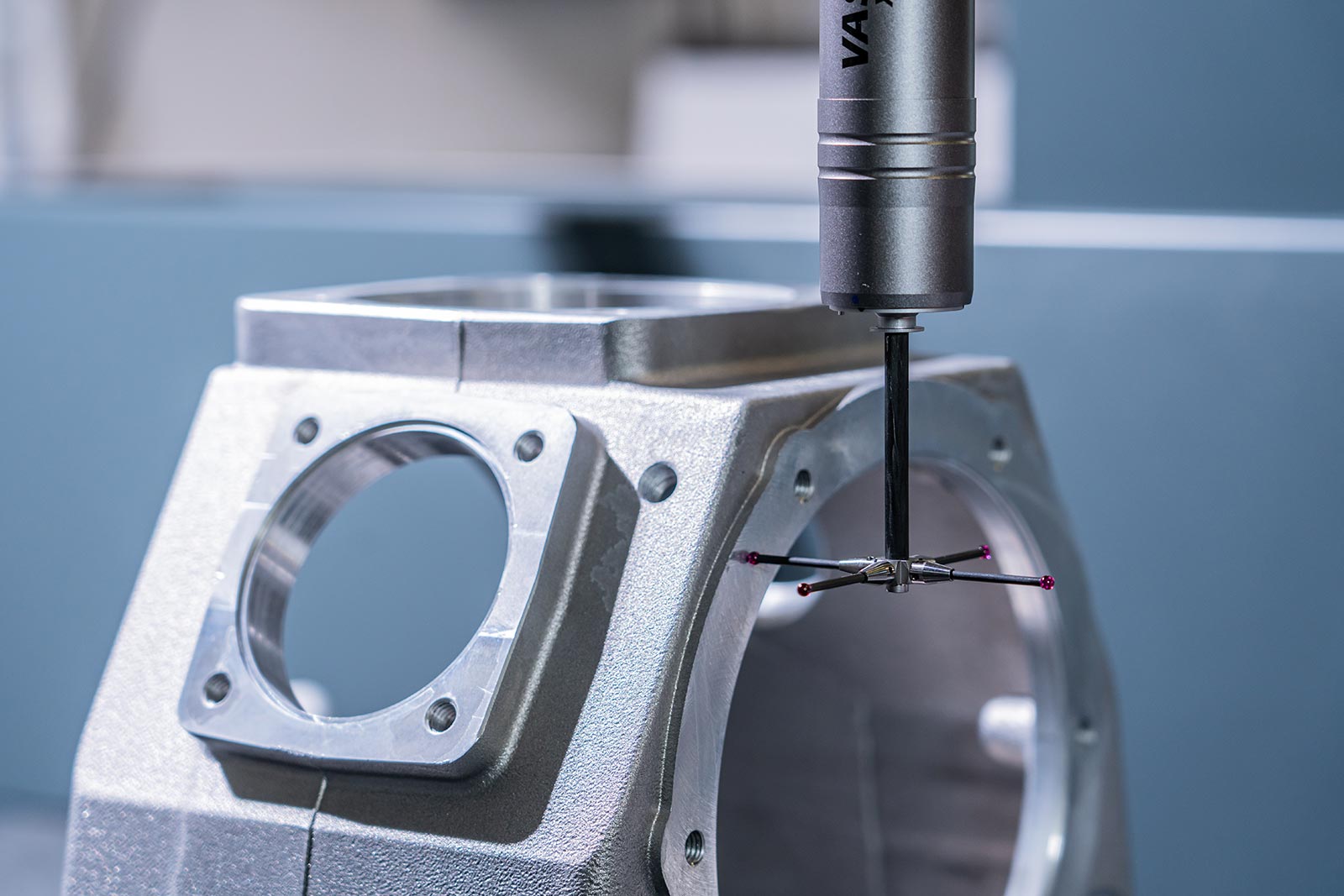

We use machines with extraordinary technical precision such as ZEISS ® , which plays a fundamental role in dimensional metrology; this allows us to detect the geometric characteristics of the pieces and to predict their behavior during use as components of more complex assemblies.

We like to see ourselves as facilitators. We create our machines so that it is easier to test yourself, to overcome limits and imagine new possibilities. Whether it’s a hobby activity, industrial application or support for emergency response activities, Coltri Compressors is here to push the bar higher, to allow you to reach the unexplored.