Filling panels restyling.

Category: Product

New design, improved quality.

The new remote filling panels are provided for recharging cylinders through storage stations or from high-pressure compressors. They can perform recharging from 225 to 300 bar. Compatible gases for refilling are: nitrogen, helium, nitrox 40% max O2.

In order to ensure maximum reliability Coltri Compressors makes a careful selection of materials and components to be used in the construction of charging panels, subjecting them to regular testing before delivery.

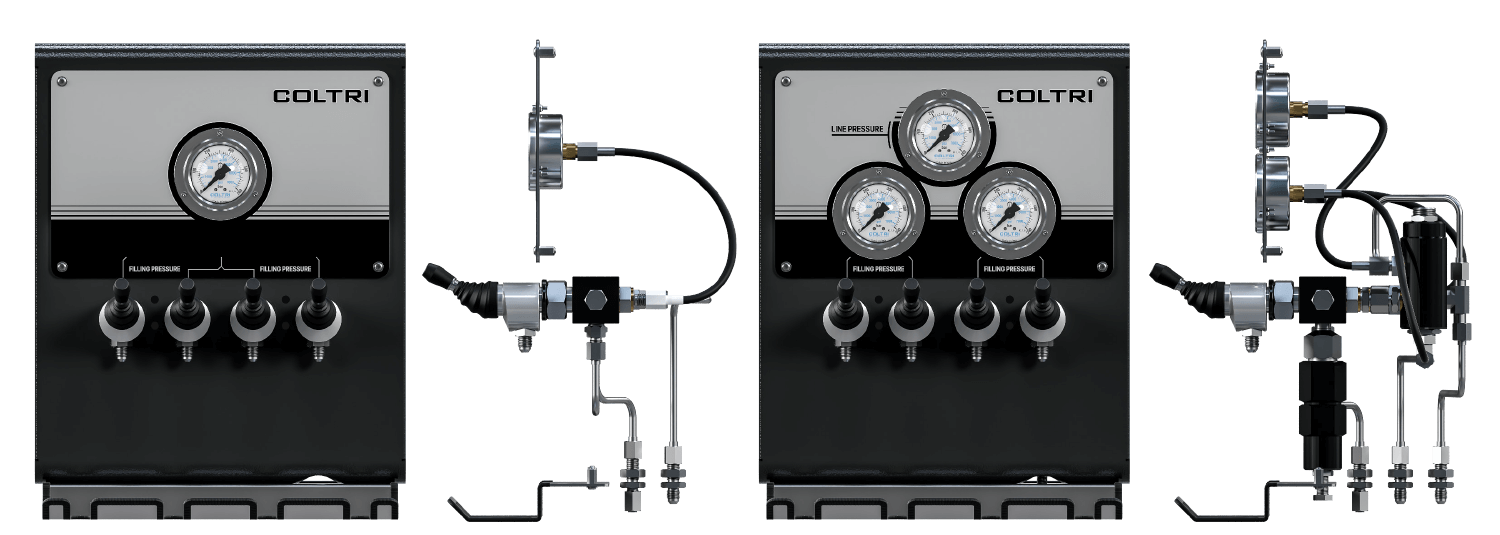

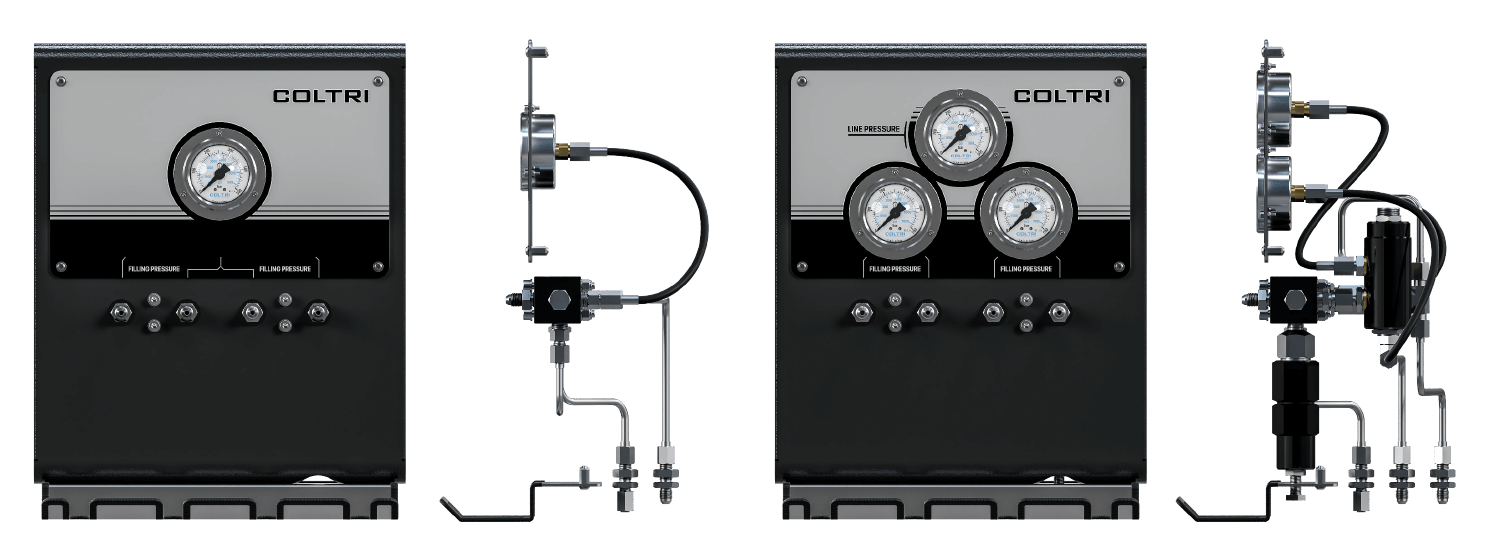

Available in the following versions:

Priority panel

The priority panel, available on dual-pressure refill panels, is an ideal solution for simple and effective storage management. It automatically manages the air flow in the filling station between the compressor, storage, and cylinders.

The user can simply connect the empty cylinders to the filling panel and open their valves.

Operation

- Compressed air from the storage system is siphoned into the cylinder.

- If the pressure drop in storage exceeds the delta P set in the pressure switch, the compressor will turn on.

- Transferring lasts until the pressure equalizes between the compressed air cylinder and the storage system.

- When pressure equilibrium is reached, the compressor fills, until the cylinder’s filling pressure is reached, the cylinder with compressed air.

- When the cylinder has been filled, a new switchover occurs through a holding valve, and the compressor fills the storage system until it automatically shuts off when the maximum filling pressure is reached.

This procedure is carried out without manual intervention.

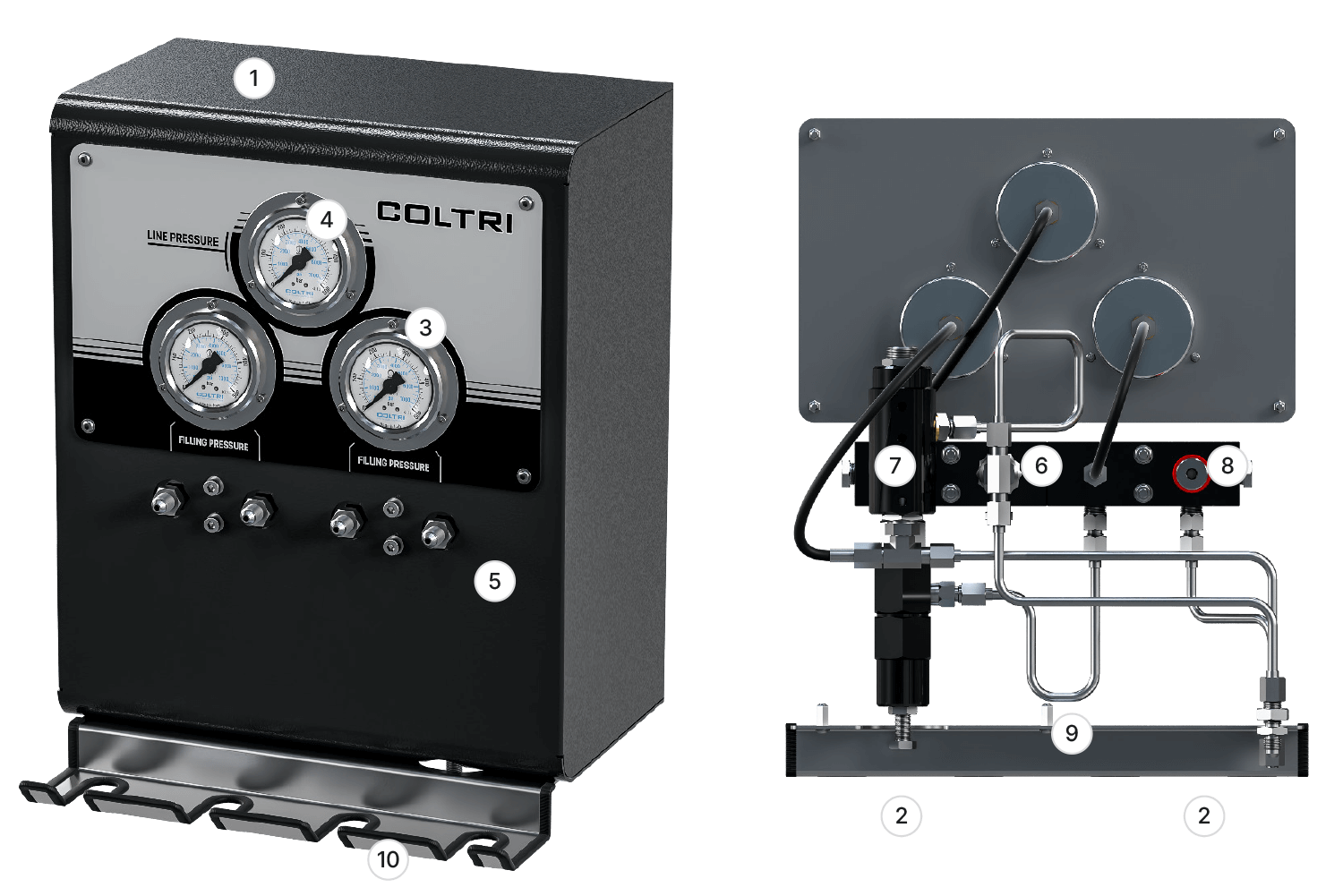

Components

- Frame

- Mounting holes

- Usage pressure gauge

- Line pressure gauge

- Priority panel

- Recharge ramp block

- Pressure reducer

- Safety valve

- Power connection fitting

- Filling hose holder

Detail of new filling panel.

Detail of new filling panel with lever taps.