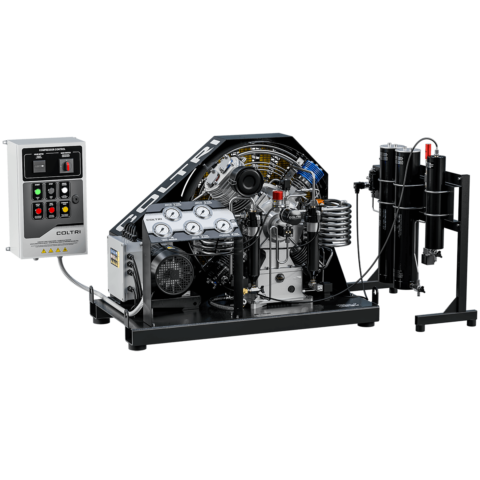

Ergo

Maximum efficiency in motion.

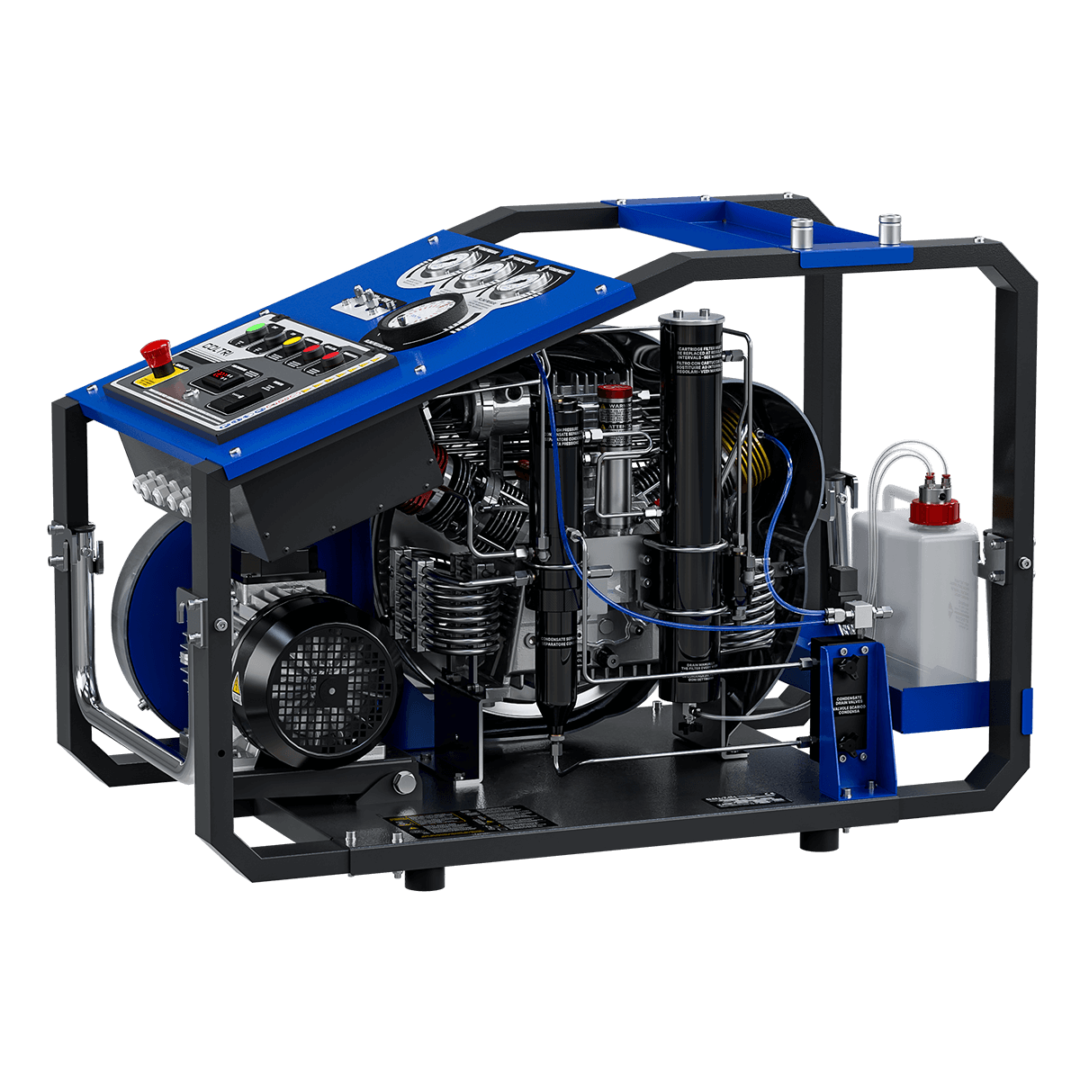

Practical to transport, ERGO stands out for its sturdiness and great operational efficiency.

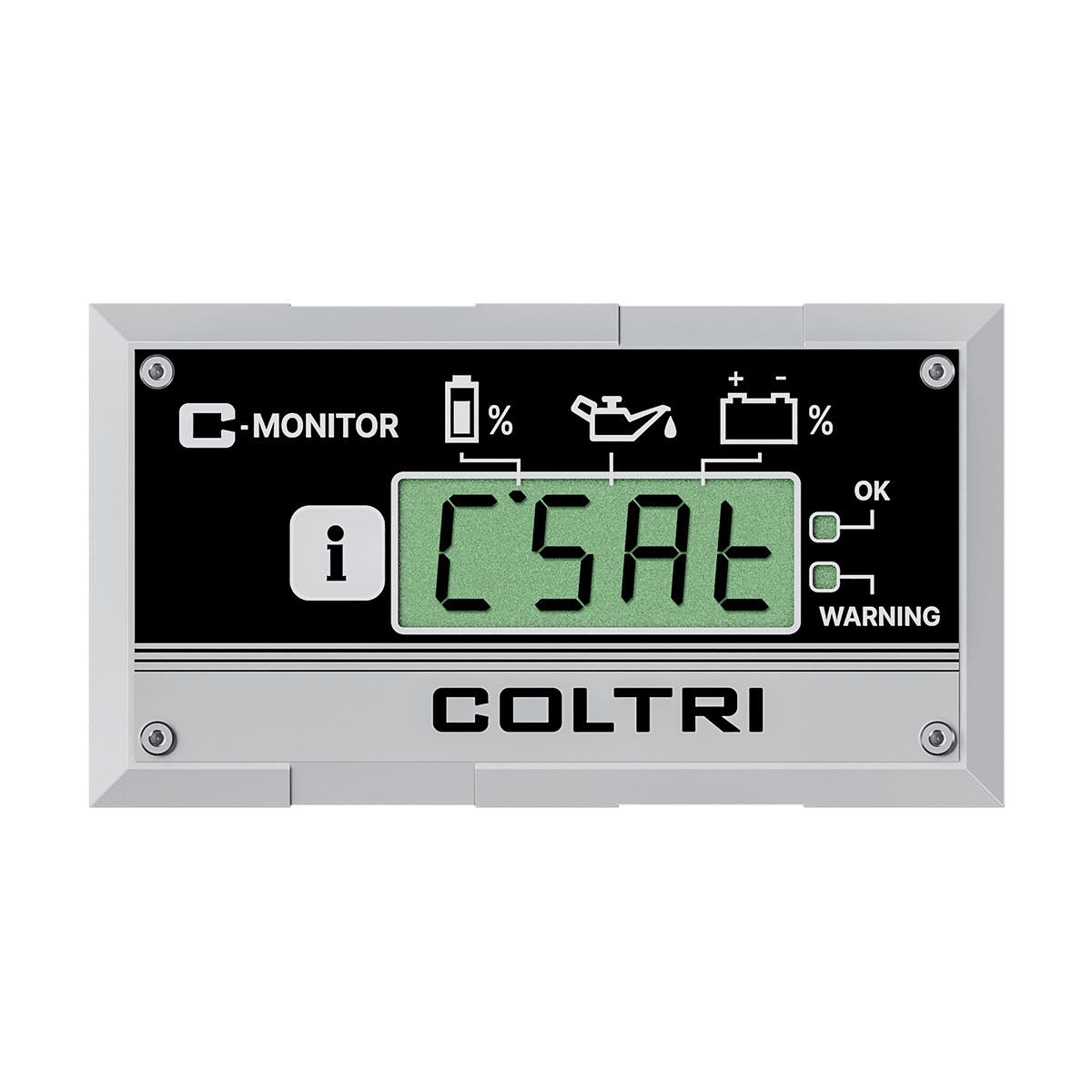

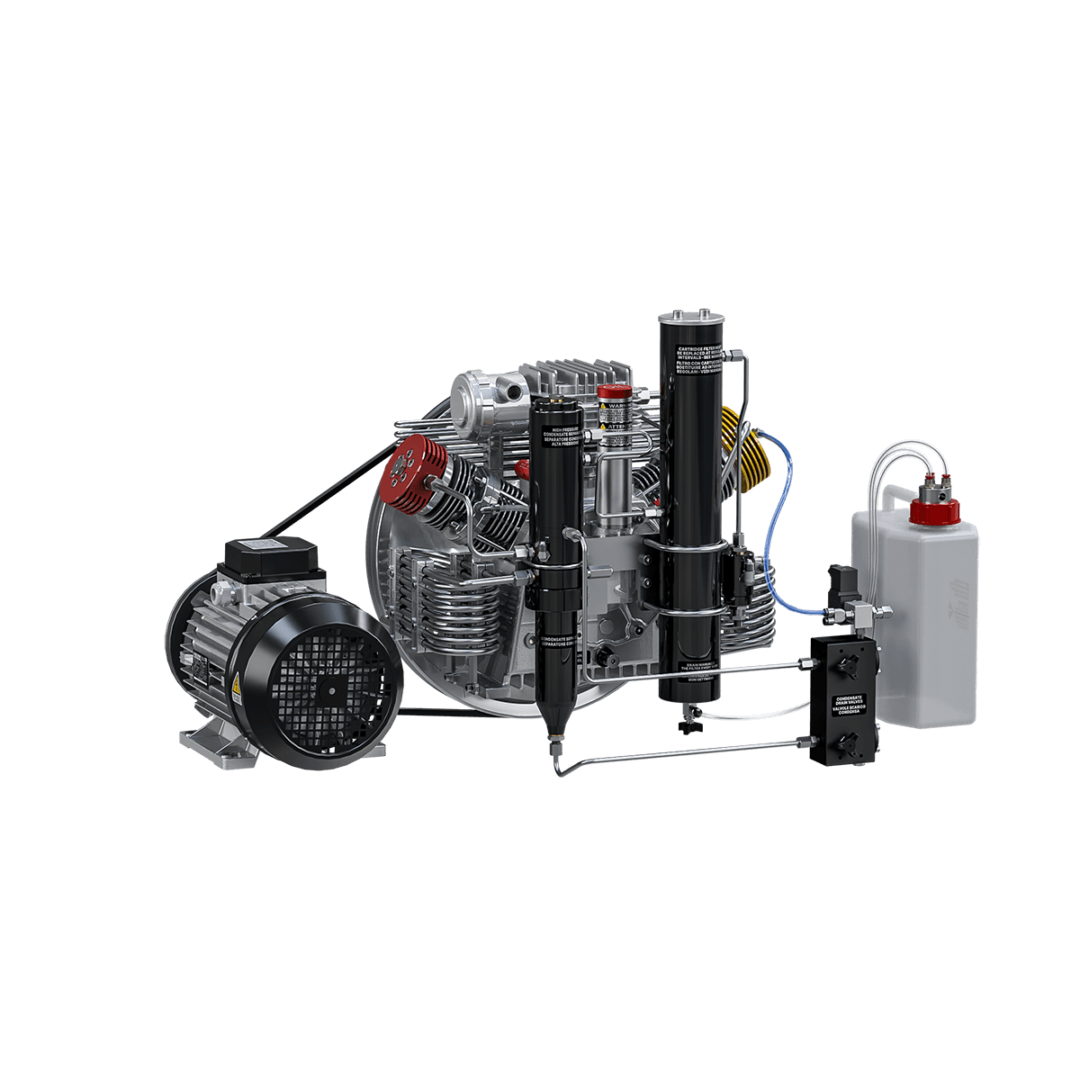

Equipped with monitoring panel complete with interstage pressure gauges, hitchhiking with adjustable pressure switch, automatic condensate drain and direction of rotation control.

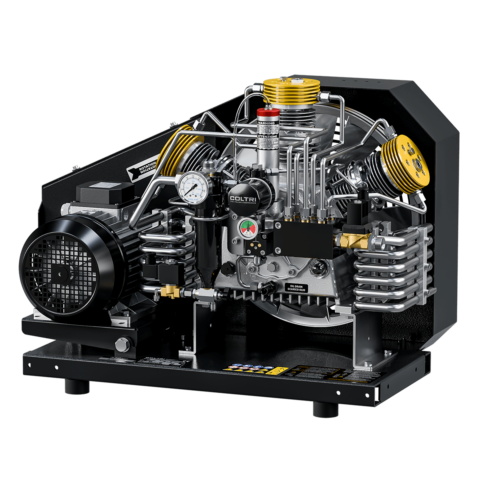

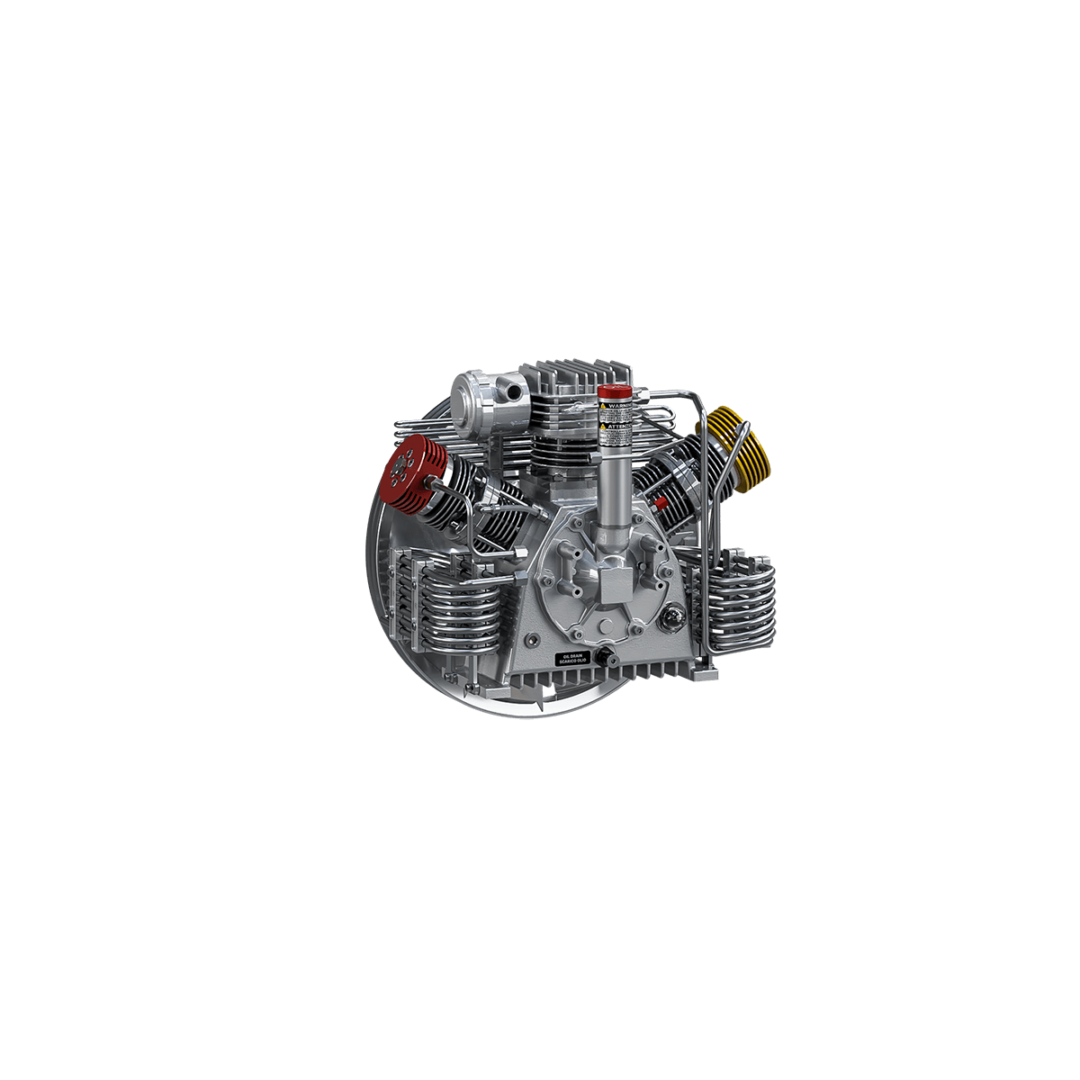

3-stage high pressure pumping unit.

- Monobloc in aluminum,

- Crankshaft in forged steel

- Splash lubrication

- Forged aluminum connecting rods

- Main roller bearings

- Roller connecting rod bearings

- 1st and 2nd stage cylinders in aluminum with hard nicasil coating

- 2nd and 3rd stage slide guide cylinders in aluminum with hard nicasil coating

- 3rd stage cylinder in special treated steel.

- Stainless steel intake and exhaust valves

- Interstage cooling pipes in stainless steel

- Separator after the 2nd and 3rd stage

- Safety valves after each stage

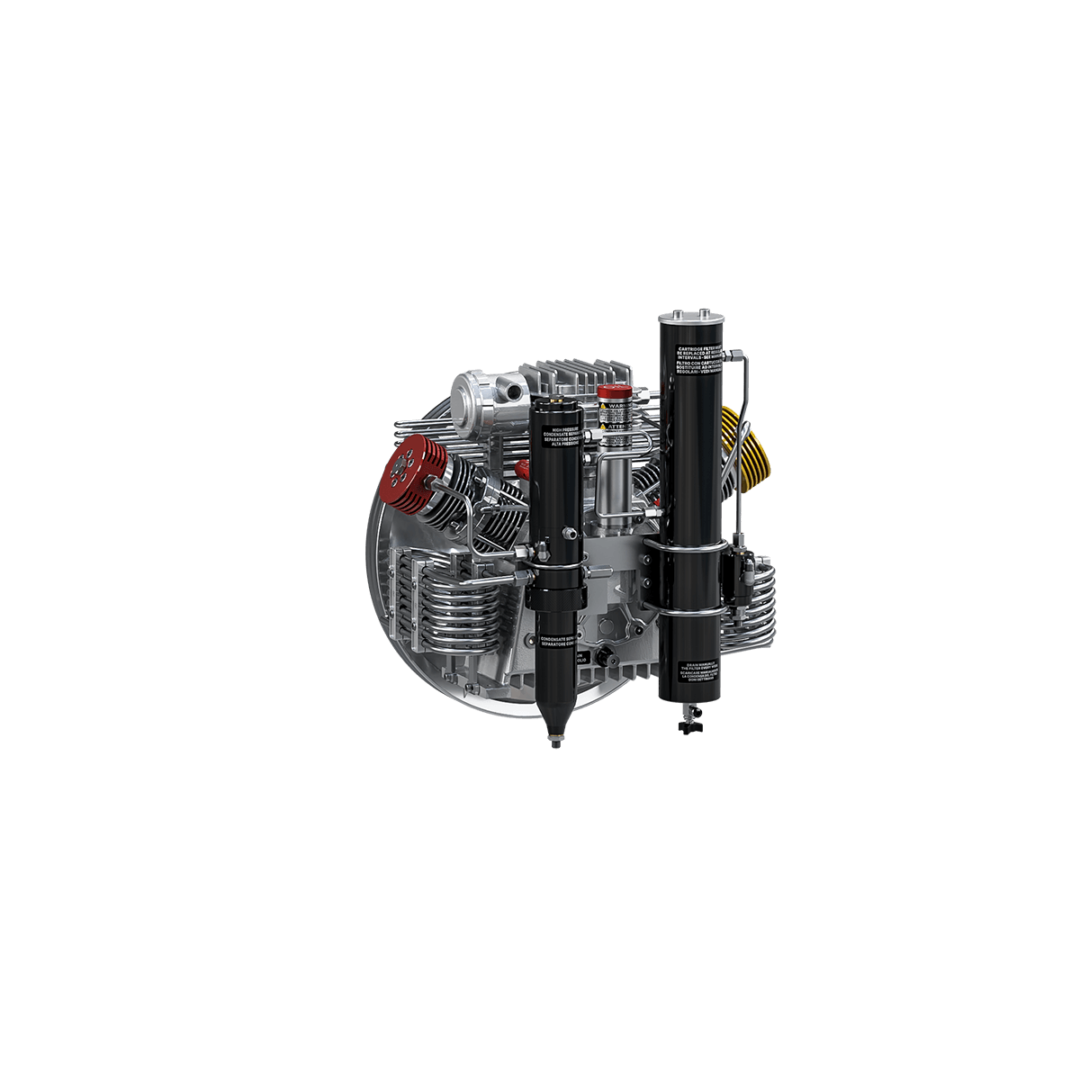

- Maxifilter purification system

- Oil level sensor

The purity of the air is achieved.

The Maxifilter purification system enables reliable treatment of breathing air according to DIN EN 12021 when using original filter cartridges. Placed after the separator of the 2nd and 3rd compressor stages and before the pressure maintenance valve to create a first fundamental moisture barrier. The filtering capacity with inlet air at 20 ° C and 200 bar is 620m³.

Electrical cabinet

- ON / OFF switch with motor protection switch.

- Electromechanical pressure switch that stops the compressor at the final pressure.

- Drainage of all separators between the individual stages and also of the final separator during compressor operation

- Timer for automatic condensate drain.

- Integrated no-load start (automatic drain every time the unit is switched off).

- 5 liter condensate collection tank, with silencer; capacity of about 3 liters, for the ecological disposal of condensate.

- Interstage pressure gauges display the working pressure for the individual compression stages. This pressure information allows you to check the tightness of the valves (inlet and outlet) of each stage and to quickly identify potential sources of failure.

Chassis

Open frame designed to facilitate maintenance operations and portability. The tilting motor-holder plate ensures constant V-belt tension. The protective casing in thermo-formed material conveys the cooling air on the cylinders and on the inter-stage pipes, guaranteeing a high compression efficiency. The control console equipped with inter-stage pressure gauges, the internal temperature indicator, the alarm presence and incorrect phase sequence, the oil lack alarm and the start stop and manual condensate drain commands allow easy management and maintenance of the compressor .

Standard equipment

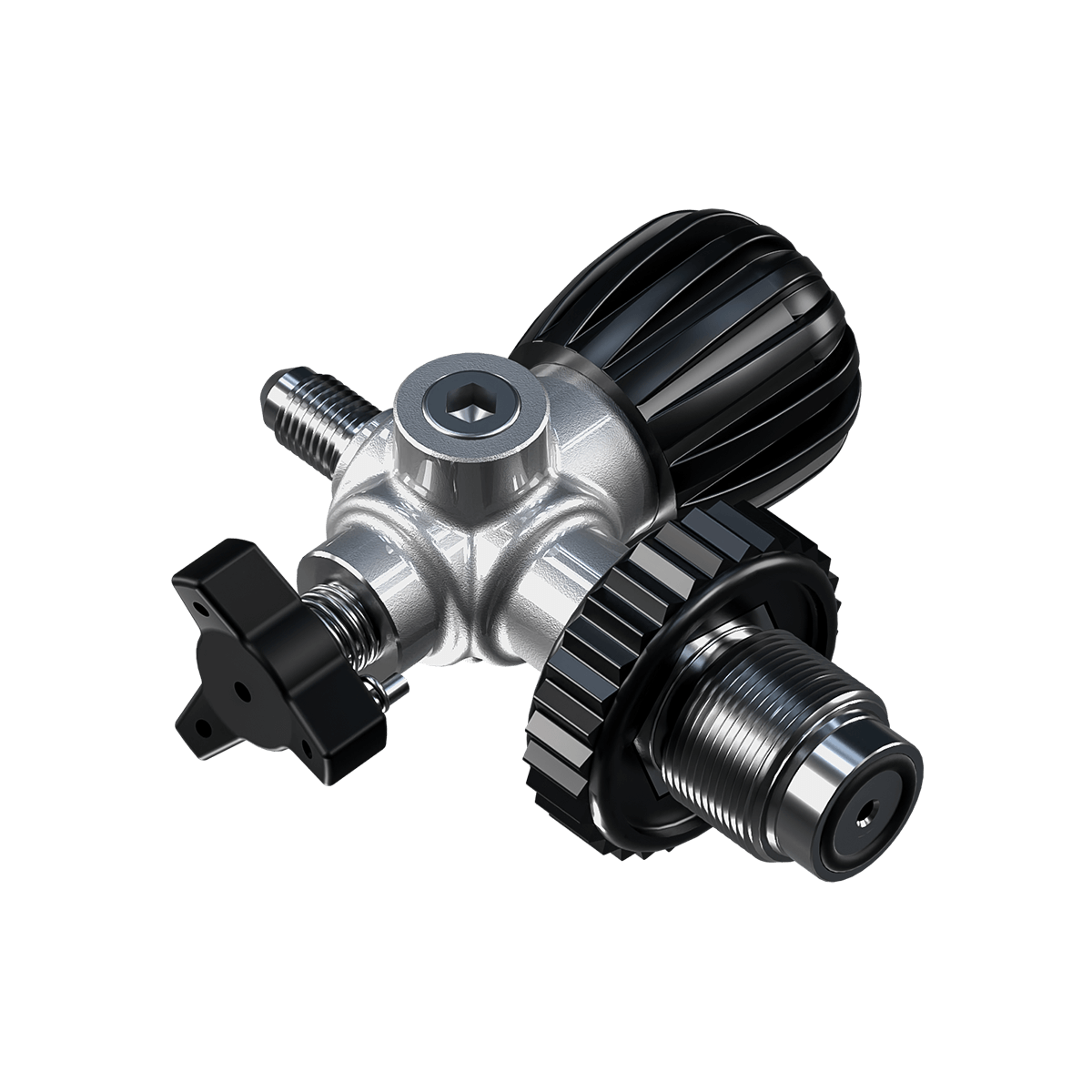

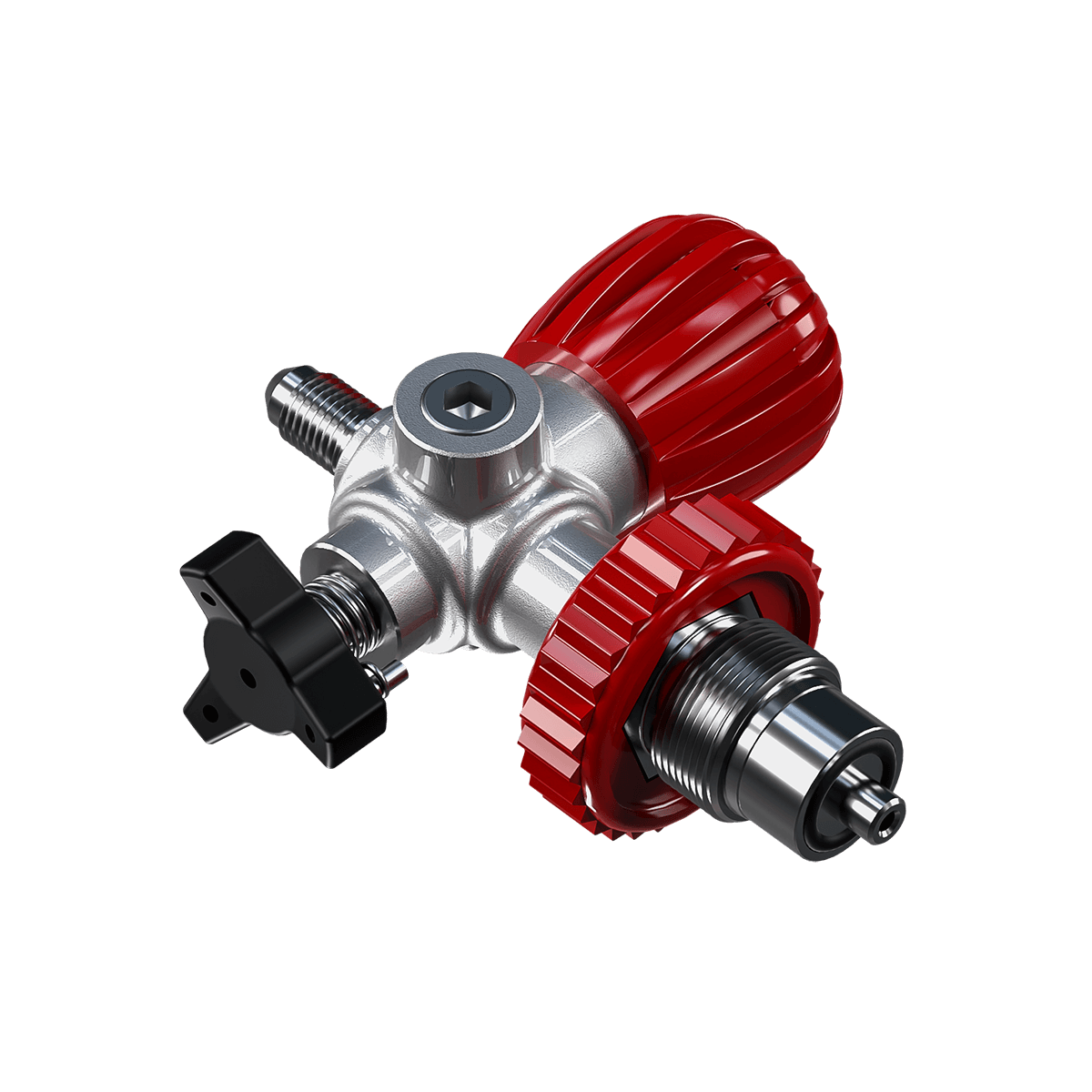

2 Cylinder connections to choose from DIN 232, DIN 300 or INT / YOKE 232 bar

2 whips 1.2m long

Pressure maintenance valve

Interstage control gauges

Maxifilter filter system

Cabin internal temperature with automatic switch-off

Automatic direction of rotation control

Pressure switch with automatic shutdown

Oil level control with automatic shutdown

Automatic condensate drain with conveyor system in the tank

Frame color Blue RAL 5002

Technical data

Type of gas

Breathing air (EN 12021) – Nitrox 40% max O2 – Helium – Nitrogen

Intake pressure

Atmospheric max 300 millibars

Nominal pressure

250 bar / 330 bar / 360 bar

Working pressure

232 bar / 300 bar / 330 bar

Max working pressure

232 bar (elettrico monofase) – 420 bar (elettrico trifase)

Permissible ambient temperature range

-10° C ÷ +40° C

Permissible altitude

0 ÷ 1.500 m SLM

Max permissible tilt

6°

Design

Fully protective cage

Operating voltage, standard

230 V; 50 Hz / 400 V; 50 Hz

Other operating voltage

On three-phase electric motor at 60Hz the power (kW / Hp) increases by 20%.230 V, 50 Hz / 230 V, 60 Hz / 440 V, 60 Hz

Oil

Synthetic Coltri Oil ST 755

Oil change interval

1 year / 1,000 h

Frame

Steel thickness 1.5 mm – color RAL 5002 + RAL 9005 Powder coating – scratch-resistant

Compressor

Charging rate

Measured during 10 liters cylinder filling from 0-200 bar tolerance +/- 5% at + 20° C ambient temperature.210 EM

210 l/min

12.6 m3/h

7.4 CFM

270 EM

270 l/min

16.2 m3/h

9.5 CFM

235 ET

235 l/min

14.1 m3/h

8.2 CFM

315 ET

315 l/min

18.9 m3/h

11.1 CFM

Purification system

Maxifilter

Cooling air flow, min.

210 EM

1.240 m3/h

270 EM

2.180 m3/h

235 ET

1.440 m3/h

315 ET

2.180 m3/h

Weight

Standard model. Weight and dimensions may vary depending on accessories.210 EM

159 kg

350 lb

270 EM

147 kg

324 lb

235 ET

159 kg

350 lb

315 ET

152 kg

335 lb

Dimensions

(W x D x H)112 x 63 x 77 cm

44.1 x 24.8 x 30.3 in

Motor

Power

210 EM

4 kW

5.5 Hp

270 EM

5,5 kW

7.5 Hp

235 ET

4 kW

5.5 Hp

315 ET

5,5 kW

7.5 Hp

Type

210 EM

Single-phase electric

270 EM

Single-phase electric

235 ET

Three-phase electric

315 ET

Single-phase electric

Operating voltage/frequency

Different voltage / frequency available on request.210 EM

230 V, 50 Hz

270 EM

230 V, 50 Hz

235 ET

400 V, 50 Hz

315 ET

400 V, 50 Hz

Rated current

210 EM

13.2 A

270 EM

13.2 A

235 ET

13.2 A

315 ET

13.2 A

Speed (RPM)

210 EM

2.800

270 EM

2.850

235 ET

2.850

315 ET

2.840

Protection class

IP55 (TEFC)

Optional

The available models of Ergo

(Non-standard models available upon request)